Measures to Address Hot Forging Die Failures in Valve Forgings

Measures to Address Hot Forging Die Failures in Valve Forgings

Oct 29, 2024

On this page

Abstract: The quality of forgings is the foundation for the quality of forged steel valves, and the hot forging die is the most fundamental element of the forging process. There are numerous factors that contribute to the failure of hot forging dies. To address the issue of die failure, multiple measures are implemented during the mold production process, including the combination of an old mold, storm treatment, GORE3755-FCG type flux-cored welding repair, and CNC forming methods to enhance the hardness of the mold cavity, extend the mold life, and improve the surface quality of valve forgings.

There are numerous factors that contribute to the failure of hot forging dies. To prevent failures, the following measures are implemented:

(1) Select a reputable mold material manufacturer to ensure that the materials meet the necessary specifications. Improving the purity of steel, particularly by reducing the contents of sulfur (S), phosphorus (P), and other impurities, is an effective measure to increase the service life of the mold. For H13 steel, the sulfur (S) content should be controlled between 0.005% and 0.008%.

(2) The mold material should not be used directly for processing finished products. It must be fully forged into a blank and then completely annealed before any further processing and forming. To address this issue, the billet should undergo significant deformation and be fully forged. Typically, the billet is alternately stretched and upset at least two or three times, followed by annealing to achieve a uniform microstructure and mechanical properties.

(3) Control the quenching and tempering temperature of the die. SCrNiMo and 5CrMnMo are traditional hot forging die steels known for their good toughness but poor thermal strength. When the temperature exceeds 400 degrees Celsius, the yield strength of the steel drops sharply. It is best to use a composite process: after heating at 850°C (using the high-temperature strengthening mechanism, with a maximum temperature of 880°C), hot oil is cooled to 150–200°C to form a small amount of martensite, and then the die is transferred to an isothermal bath at 280–300°C for 2–3 hours to ensure uniform die temperature and avoid the formation of upper bainite. Afterward, tempering is performed. This method yields the most ideal comprehensive mechanical properties for the die. The quenching temperature for H13 steel must not exceed 1050°C. It should be pre-cooled to about 800°C for oil cooling, removed from the oil at about 350°C, and air-cooled to 180–200°C on the surface for tempering, which should be performed twice.

(4) To prevent the second type of temper brittleness, oil cooling can be applied after tempering. When the oil cools to about 100°C, the oil should be drained from the groove. Oil cooling after tempering also generates thermal stress; therefore, the die can be tempered again at 190–200°C.

(5)The hardness difference between the dovetail and the dovetail groove is a result of tempering. The hardness of the dovetail is 35–40 HRC, while the hardness of the dovetail groove is 45–50 HRC. This process improves the service life and safety factor of the mold. Tempering can be performed in stages in the salt furnace, with the tempering temperature of the dovetail part increased to deliberately create the hardness difference. This approach ensures that the dovetail part has lower hardness, good toughness, and is less prone to brittle fracture. The higher hardness of the cavity part extends the mold's service life and enhances the quality of the forgings, thereby reducing production costs. By adjusting the hardness difference, the Z41H-300LB-50 forging die can increase its service life by 5–8 times.

(6) Before forging, strictly preheat the forging die, ensuring that the surface temperature is at least 200°C before forging can begin.

(7)The swallow groove part can also undergo surfacing welding and then be heated for tempering (by 50–80°C) to reduce the hardness of the dovetail part. The cavity hardness is 53–57 HRC. To ensure the quality of the forging die and prevent failure, the swallow groove part undergoes storm treatment and surfacing before swallow groove machining. GORE 3755 flux-cored welding wire is used for surfacing repair. This welding wire is a flux-cored variety developed in parallel with similar foreign welding wires. The alloy system is a low-carbon Cr-Mo-W-V alloy with a metallographic structure of martensite and dispersed precipitation of secondary carbides. It offers high-temperature red hardness, excellent thermal strength, metal-to-metal wear resistance at high temperatures, high deposition efficiency, strong anti-porosity properties, and a post-welding hardness of 50–54 HRC. This repair method increases mold life by more than 200%, delivering clear benefits.

a) Shielding gas: 20%CO2 +80%Ar, shielding gas flow: 20

L/min

b) Welding parameters: I=270A (250-300A), U=29V (28-30V)

Table 1 Chemical composition of weld metal

There are numerous factors that contribute to the failure of hot forging dies. To prevent failures, the following measures are implemented:

(1) Select a reputable mold material manufacturer to ensure that the materials meet the necessary specifications. Improving the purity of steel, particularly by reducing the contents of sulfur (S), phosphorus (P), and other impurities, is an effective measure to increase the service life of the mold. For H13 steel, the sulfur (S) content should be controlled between 0.005% and 0.008%.

(2) The mold material should not be used directly for processing finished products. It must be fully forged into a blank and then completely annealed before any further processing and forming. To address this issue, the billet should undergo significant deformation and be fully forged. Typically, the billet is alternately stretched and upset at least two or three times, followed by annealing to achieve a uniform microstructure and mechanical properties.

(3) Control the quenching and tempering temperature of the die. SCrNiMo and 5CrMnMo are traditional hot forging die steels known for their good toughness but poor thermal strength. When the temperature exceeds 400 degrees Celsius, the yield strength of the steel drops sharply. It is best to use a composite process: after heating at 850°C (using the high-temperature strengthening mechanism, with a maximum temperature of 880°C), hot oil is cooled to 150–200°C to form a small amount of martensite, and then the die is transferred to an isothermal bath at 280–300°C for 2–3 hours to ensure uniform die temperature and avoid the formation of upper bainite. Afterward, tempering is performed. This method yields the most ideal comprehensive mechanical properties for the die. The quenching temperature for H13 steel must not exceed 1050°C. It should be pre-cooled to about 800°C for oil cooling, removed from the oil at about 350°C, and air-cooled to 180–200°C on the surface for tempering, which should be performed twice.

(4) To prevent the second type of temper brittleness, oil cooling can be applied after tempering. When the oil cools to about 100°C, the oil should be drained from the groove. Oil cooling after tempering also generates thermal stress; therefore, the die can be tempered again at 190–200°C.

(5)The hardness difference between the dovetail and the dovetail groove is a result of tempering. The hardness of the dovetail is 35–40 HRC, while the hardness of the dovetail groove is 45–50 HRC. This process improves the service life and safety factor of the mold. Tempering can be performed in stages in the salt furnace, with the tempering temperature of the dovetail part increased to deliberately create the hardness difference. This approach ensures that the dovetail part has lower hardness, good toughness, and is less prone to brittle fracture. The higher hardness of the cavity part extends the mold's service life and enhances the quality of the forgings, thereby reducing production costs. By adjusting the hardness difference, the Z41H-300LB-50 forging die can increase its service life by 5–8 times.

(6) Before forging, strictly preheat the forging die, ensuring that the surface temperature is at least 200°C before forging can begin.

(7)The swallow groove part can also undergo surfacing welding and then be heated for tempering (by 50–80°C) to reduce the hardness of the dovetail part. The cavity hardness is 53–57 HRC. To ensure the quality of the forging die and prevent failure, the swallow groove part undergoes storm treatment and surfacing before swallow groove machining. GORE 3755 flux-cored welding wire is used for surfacing repair. This welding wire is a flux-cored variety developed in parallel with similar foreign welding wires. The alloy system is a low-carbon Cr-Mo-W-V alloy with a metallographic structure of martensite and dispersed precipitation of secondary carbides. It offers high-temperature red hardness, excellent thermal strength, metal-to-metal wear resistance at high temperatures, high deposition efficiency, strong anti-porosity properties, and a post-welding hardness of 50–54 HRC. This repair method increases mold life by more than 200%, delivering clear benefits.

a) Shielding gas: 20%CO2 +80%Ar, shielding gas flow: 20

L/min

b) Welding parameters: I=270A (250-300A), U=29V (28-30V)

Table 1 Chemical composition of weld metal

| Element | C | Mn | Si | Cr | Mo | W | V | Others | Hardness (HRC) |

| GORE 3755 | <0.4 | <1.0 | <1.0 | 4.5-8.0 | <3.0 | <2.5 | <1.0 | <2.0 | 51-57 |

After welding, maintain heat and allow the mold to cool slowly to normal temperature before entering the furnace for tempering heat treatment. The tempering temperature is 550°C, with a heating time of 2-3 hours and a holding time of 6-8 hours. After opening the furnace, allow the mold to cool slowly to normal temperature again. Large molds can also undergo a second tempering cycle. The specific process is shown in the welding flow chart in Figure 9.

Figure 9 welding flow chart

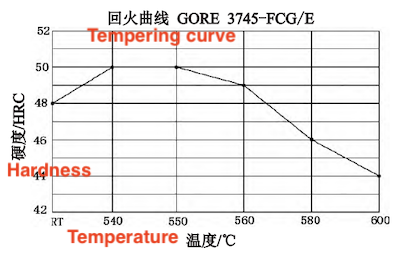

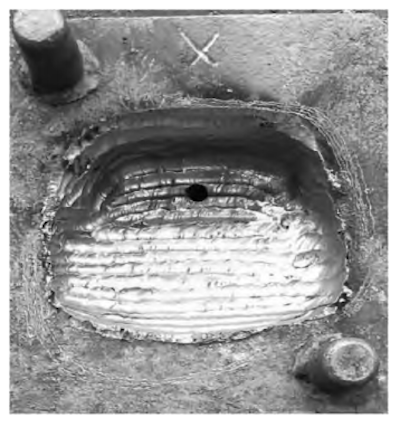

As shown in Figure 10, after tempering at 540-560°C, the cavity reaches its maximum hardness value, while the matrix hardness decreases to approximately HRC 37. This creates the optimal hardness difference. The reduction in matrix hardness helps prevent cracking, while the increased cavity hardness improves red hardness, effectively doubling the mold’s service life. Figure 11 shows the cavity after storm treatment for crack repair, and Figure 12 depicts the cavity after the CORE 3755 surfacing procedure. Figure 13 illustrates the mold after welding, showcasing a smooth mold surface finish.

Figure 10 Post-weld tempering data

Figure 11 Cavity after storm treatment

Figure 12 Cavity after CORE 3755 welding wire surfacing

Figure 13 Valve body forging die forming diagram

By implementing measures for hot forging dies, the combination of old mold storm treatment, GORE3755-FCG type flux-cored welding wire surfacing repair, and CNC forming method is used to enhance mold cavity hardness, double mold service life, and improve the surface quality of valve forgings.

Next: The Multi-Directional Die Forging Process of High-Pressure Plug Valves

Previous: Analysis of the Causes of Hot Forging Die Failure of Valve Forgings

News

About Us

Best Categories

Useful Links