The Machining of Oblique Holes of Forged Steel Globe Valve Bodies

The Machining of Oblique Holes of Forged Steel Globe Valve Bodies

Jun 03, 2021

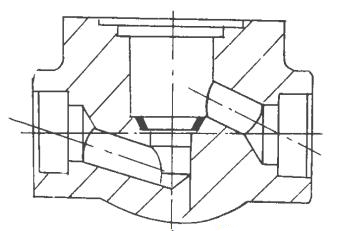

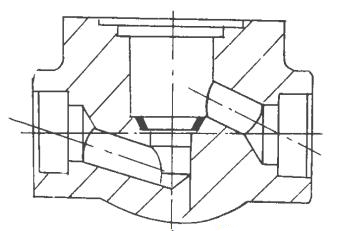

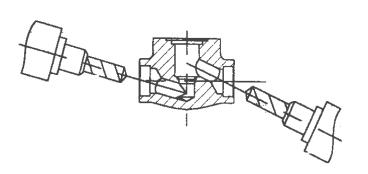

The compact forged steel globe valve has small sizes, light weights, good strength and reasonable structure, which is welcomed by users. The machining processes of the globe valve body (Figure 1) are as follows: die forging valves → heat treatment → shot blasting → inspection → machining middle flange planes, seam allowance and middle holes → machining both end faces, socket and flow holes → drilling the flange bolt holes of middle flanges → drilling the oblique holes at both ends → surfacing welding for sealing ports → machining sealing surfaces → deburring → inspection of finished products. Among them, drilling oblique holes at both ends is difficult and the processing time is long, which affects the production schedule.

Figure 1 Globe valve bodies

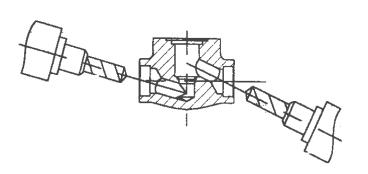

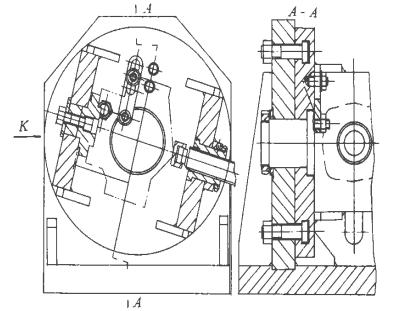

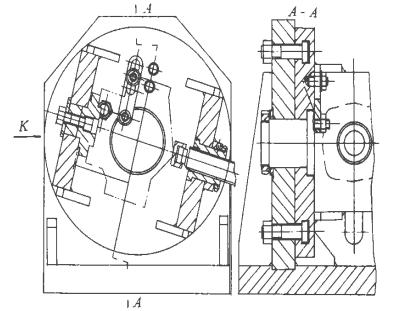

If forged steel globe valves are produced in large quantities, the oblique holes of the valve body can be processed with special equipment (Figure 2), which is conducive to improving product quality. However, the special machine tool has little adaptability. If the product specification is changed, the equipment needs to be adjusted again. Adjusting equipment is time-consuming and labor-intensive, and it is not suitable for producing valves in small quantities. In order to meet the processing needs of single and small batch valve bodies, adjustable drilling dies for drilling oblique holes were designed and manufactured (Figure 3). The fixture adopts the large plane of the middle flange and positioning of seam allowance to limit the five degrees of freedom of the valve body. The other degree of freedom is eliminated by the adjustable supporting nail. The positioning surface is large. The positioning is safe and reasonable, and the workpiece is convenient to be clamped, which save time and effort. The cone angle of the drill bit used is 110° when a hole is drilled.

Figure 2 Special machine tools for processing oblique holes

Figure 3 Adjustable dies of drilling oblique holes for globe valve bodies

The adjustable die of drilling oblique holes has a wide processing range. One type can replace dozens of drilling hole fixtures, which not only saves a lot of capital for tooling, but also saves a lot of preparation time for production.

Figure 1 Globe valve bodies

If forged steel globe valves are produced in large quantities, the oblique holes of the valve body can be processed with special equipment (Figure 2), which is conducive to improving product quality. However, the special machine tool has little adaptability. If the product specification is changed, the equipment needs to be adjusted again. Adjusting equipment is time-consuming and labor-intensive, and it is not suitable for producing valves in small quantities. In order to meet the processing needs of single and small batch valve bodies, adjustable drilling dies for drilling oblique holes were designed and manufactured (Figure 3). The fixture adopts the large plane of the middle flange and positioning of seam allowance to limit the five degrees of freedom of the valve body. The other degree of freedom is eliminated by the adjustable supporting nail. The positioning surface is large. The positioning is safe and reasonable, and the workpiece is convenient to be clamped, which save time and effort. The cone angle of the drill bit used is 110° when a hole is drilled.

Figure 2 Special machine tools for processing oblique holes

Figure 3 Adjustable dies of drilling oblique holes for globe valve bodies

The adjustable die of drilling oblique holes has a wide processing range. One type can replace dozens of drilling hole fixtures, which not only saves a lot of capital for tooling, but also saves a lot of preparation time for production.

Next: Processing Oblique Channels of Forged Steel Globe Valve Bodies (Part One)

Previous: Stellite Alloy Surfacing Repair Processes of 15CrMo Forged Gate Valves (Part Three)

News

About Us

Best Categories

Useful Links