Stellite Alloy Surfacing Repair Processes of 15CrMo Forged Gate Valves (Part Three)

Stellite Alloy Surfacing Repair Processes of 15CrMo Forged Gate Valves (Part Three)

May 22, 2021

3.1.3 Intelligent temperature control

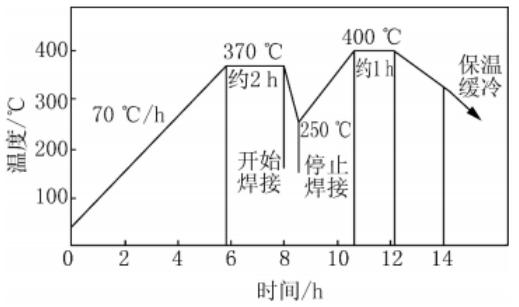

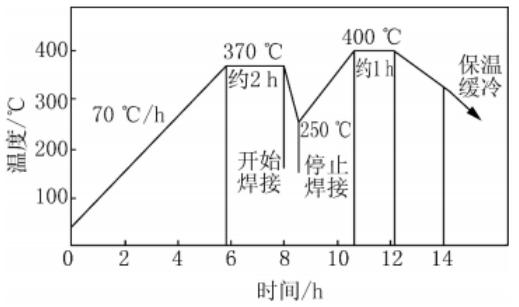

The temperature rise rate should not exceed 70℃/h to avoid the partial excessive temperature of the valve body and valve seat, which will affect the deformation of the valve body. After it exceeds 300°C, the heating rate is allowed to be appropriately reduced. When the temperature rises to about 370°C, you can weld the parts that need surfacing after heat preserving for about 2 hours. The schematic diagram of the temperature control heat treatment process is shown in Figure 2.

Figure 2 The process diagram of intelligent temperature control heat treatment

3.2 Surfacing of alloy surfaces

3.2.1 Basic requirements for surfacing layers

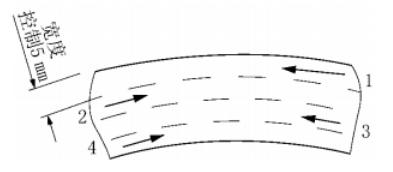

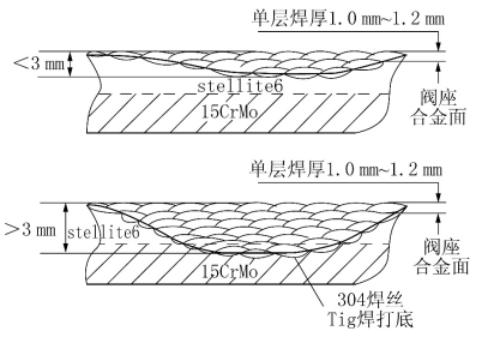

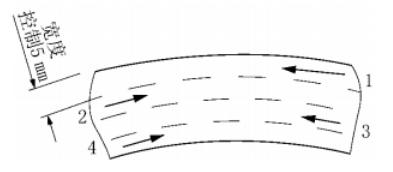

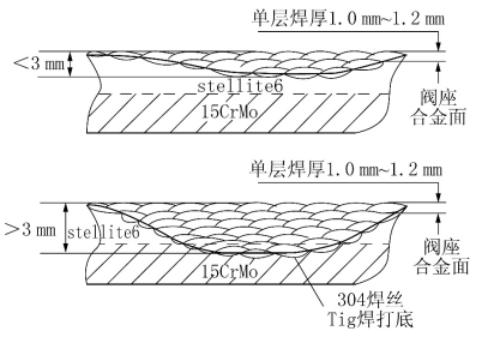

The welding material is the Stellite6 electrode, which is convenient for on-site construction. The diameter of the electrode is φ1.2 mm, which is beneficial to controlling the welding heat input and the width of the welding bead. According to the surfacing welding range determined by the inspection, build-up weld the surface layer by layer. Weld the surface continuously based on the sequences shown in figure 3. The thickness between surfacing layers is 1.0 mm to 1.2 mm, adopting low power, multi-layer, and multi-pass welding. When the thickness of the sealing surface alloy is missing more than 3 mm, it is necessary to use 304 welding wire as a transition layer to prevent the alloy from cracking. After each layer is welded, use a straight steel plate to detect the surfacing height, and the top surface of the transition layer reaches the joint part of the original base material and the alloy. The surfacing treatment methods of different damage depths are shown in Figure 4.

Figure 3 The schematic diagram of the sequence of the welding bead

Figure 4 The schematic diagram of surfacing treatment methods for different damage depths

The partial surfacing surface of the missing part of the alloy is 1mm to 2mm higher than the undamaged valve seat surface, which not only reserves enough rough grinding height to remove impurities on the surfacing surface, but also helps control the workload of grinding. In the rough grinding process, blindly grinding must be avoided to prevent excessive partial grinding depth, resulting in the loss of secondary alloys and repair failure.

3.2.2 Temperature control in the welding and heat treatment processes

In order to ensure safety, the power supply must be disconnected and the heating must be stopped before the welding process starts. In the welding process, use an infrared thermometer to monitor the temperature of the valve body and valve seat. When the temperature drops to 250°C, the operation must be stopped. Continue to heat till the temperature gets to 350°C to 370°C, and cut off the power. Repeat this process again and again, and the time of repeating this process depends on is determined by the repair workload of the valve seat. After the welding is completed, continue to heat to 400°C. Cut off the power and cover the insulation layer after heat preservation for one hour. Naturally cool to ambient temperature. The heat treatment process is based on the intelligent temperature control process.

3.2.3 Repair of surfacing surfaces

After the surfacing surface is processed, if there are small holes or cracks, the surface should be repaired. When repairing small shrinkage lines, the weldment needs to be partially preheated first, and then adopt argon arc welding on the part which needs to be repaired. The method of welding rod surfacing is adopted. In the repair process, the excessive melting of original stellite surfacing should be avoided. If the surface with gas holes needs to be repaired, it is necessary to remove the original surfacing layer and build-up weld again. If the surface with cracks needs to be repaired, the surfacing layer near the crack should be turned or ground; preheat the weldment before repairing.

3.2.4 Quality inspection of surfacing surfaces

Perform penetrant inspection on the welded parts after surfacing, and no cracks or gas holes are allowed. If conditions permit, check the hardness of the surfacing surface to see if it meets the quality requirements.

3.3 Processing of surfacing surfaces

Use a vertical lathe or a portable flange lathe for the surfacing surface. When conditions do not permit, you can use a hand-held smoother to partially polish raised points. When the height of the surfacing surface to be surfaced is from 0.2 mm to 0.3 mm, the grinding disc is used to grind the sealing surface of the valve seat. The grinding process is carried out in sequence: rough grinding, intermediate grinding and fine grinding, ensuring that the surface finishment of the valve seat is not less than Ra 0.4. Finally, check the repair result on site according to the sealing test of the valve seat.

4. Conclusion

With the increase of the operating time of chemical plants, the damage of the forged gate valve becomes more serious, and the requirements for the key process of valve maintenance are higher and higher. Although the Stellite6 alloy surfacing technology has been maturely applied in the factory, it is still a difficulty faced by domestic maintenance manufacturers due to the limitation of on-site construction equipment conditions. Although the alloy on-site surfacing repair process mentioned in this article can meet engineering applications, its welding process still needs process qualification to optimize and adjust the surfacing process parameters, so that hardness, density and other indicators of the surfacing layer are digitized; the surfacing process can be more stable to guide the on-site repairing.

The temperature rise rate should not exceed 70℃/h to avoid the partial excessive temperature of the valve body and valve seat, which will affect the deformation of the valve body. After it exceeds 300°C, the heating rate is allowed to be appropriately reduced. When the temperature rises to about 370°C, you can weld the parts that need surfacing after heat preserving for about 2 hours. The schematic diagram of the temperature control heat treatment process is shown in Figure 2.

Figure 2 The process diagram of intelligent temperature control heat treatment

3.2 Surfacing of alloy surfaces

3.2.1 Basic requirements for surfacing layers

The welding material is the Stellite6 electrode, which is convenient for on-site construction. The diameter of the electrode is φ1.2 mm, which is beneficial to controlling the welding heat input and the width of the welding bead. According to the surfacing welding range determined by the inspection, build-up weld the surface layer by layer. Weld the surface continuously based on the sequences shown in figure 3. The thickness between surfacing layers is 1.0 mm to 1.2 mm, adopting low power, multi-layer, and multi-pass welding. When the thickness of the sealing surface alloy is missing more than 3 mm, it is necessary to use 304 welding wire as a transition layer to prevent the alloy from cracking. After each layer is welded, use a straight steel plate to detect the surfacing height, and the top surface of the transition layer reaches the joint part of the original base material and the alloy. The surfacing treatment methods of different damage depths are shown in Figure 4.

Figure 3 The schematic diagram of the sequence of the welding bead

Figure 4 The schematic diagram of surfacing treatment methods for different damage depths

The partial surfacing surface of the missing part of the alloy is 1mm to 2mm higher than the undamaged valve seat surface, which not only reserves enough rough grinding height to remove impurities on the surfacing surface, but also helps control the workload of grinding. In the rough grinding process, blindly grinding must be avoided to prevent excessive partial grinding depth, resulting in the loss of secondary alloys and repair failure.

3.2.2 Temperature control in the welding and heat treatment processes

In order to ensure safety, the power supply must be disconnected and the heating must be stopped before the welding process starts. In the welding process, use an infrared thermometer to monitor the temperature of the valve body and valve seat. When the temperature drops to 250°C, the operation must be stopped. Continue to heat till the temperature gets to 350°C to 370°C, and cut off the power. Repeat this process again and again, and the time of repeating this process depends on is determined by the repair workload of the valve seat. After the welding is completed, continue to heat to 400°C. Cut off the power and cover the insulation layer after heat preservation for one hour. Naturally cool to ambient temperature. The heat treatment process is based on the intelligent temperature control process.

3.2.3 Repair of surfacing surfaces

After the surfacing surface is processed, if there are small holes or cracks, the surface should be repaired. When repairing small shrinkage lines, the weldment needs to be partially preheated first, and then adopt argon arc welding on the part which needs to be repaired. The method of welding rod surfacing is adopted. In the repair process, the excessive melting of original stellite surfacing should be avoided. If the surface with gas holes needs to be repaired, it is necessary to remove the original surfacing layer and build-up weld again. If the surface with cracks needs to be repaired, the surfacing layer near the crack should be turned or ground; preheat the weldment before repairing.

3.2.4 Quality inspection of surfacing surfaces

Perform penetrant inspection on the welded parts after surfacing, and no cracks or gas holes are allowed. If conditions permit, check the hardness of the surfacing surface to see if it meets the quality requirements.

3.3 Processing of surfacing surfaces

Use a vertical lathe or a portable flange lathe for the surfacing surface. When conditions do not permit, you can use a hand-held smoother to partially polish raised points. When the height of the surfacing surface to be surfaced is from 0.2 mm to 0.3 mm, the grinding disc is used to grind the sealing surface of the valve seat. The grinding process is carried out in sequence: rough grinding, intermediate grinding and fine grinding, ensuring that the surface finishment of the valve seat is not less than Ra 0.4. Finally, check the repair result on site according to the sealing test of the valve seat.

4. Conclusion

With the increase of the operating time of chemical plants, the damage of the forged gate valve becomes more serious, and the requirements for the key process of valve maintenance are higher and higher. Although the Stellite6 alloy surfacing technology has been maturely applied in the factory, it is still a difficulty faced by domestic maintenance manufacturers due to the limitation of on-site construction equipment conditions. Although the alloy on-site surfacing repair process mentioned in this article can meet engineering applications, its welding process still needs process qualification to optimize and adjust the surfacing process parameters, so that hardness, density and other indicators of the surfacing layer are digitized; the surfacing process can be more stable to guide the on-site repairing.

Next: The Machining of Oblique Holes of Forged Steel Globe Valve Bodies

Previous: Stellite Alloy Surfacing Repair Processes of 15CrMo Forged Gate Valves (Part Two)

News

About Us

Best Categories

Useful Links