The Difference between Soft and Hard Sealing in High-Pressure Ball Valves

The Difference between Soft and Hard Sealing in High-Pressure Ball Valves

Mar 25, 2024

When it comes to the use of high-pressure ball valves, there's a distinct difference between soft and hard sealing, primarily in their structural mechanisms and manufacturing standards.

Structural Mechanism:

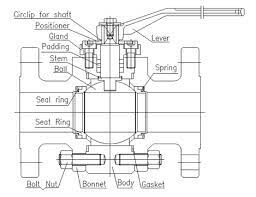

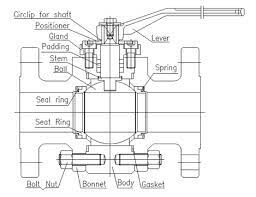

Hard sealing in high-pressure ball valves involves metal-to-metal sealing between the ball and the seat, requiring precision machining and typically used in high-pressure applications, usually above 35MPa. On the other hand, soft sealing involves sealing between metal and non-metal materials like nylon or polytetrafluoroethylene (PTFE), maintaining similar manufacturing standards.

Sealing Material:

Soft and hard sealing refer to the sealing material of the valve seat. Hard sealing utilizes precision-machined seat materials like stainless steel or copper to ensure accuracy in conjunction with the valve core (ball). In contrast, soft sealing involves non-metallic sealing materials embedded in the seat, offering lower requirements for machining precision due to the elasticity of the soft sealing material.

Manufacturing Process:

In complex environments such as those found in chemical and mechanical industries, where high temperatures, high pressures, and corrosive media are common, advancements in technology have allowed for the effective use of various materials and manufacturing processes, leading to the widespread adoption of hard-sealing ball valves.

Usage Conditions:

Soft sealing generally achieves high levels of sealing, while hard sealing can vary depending on requirements. Soft sealing requires fire prevention measures as the material may leak under high temperatures, whereas hard sealing doesn't face this issue. Hard sealing can typically withstand higher pressures than soft sealing, although soft sealing may not be suitable for certain corrosive media. Additionally, hard sealing valves are generally more expensive than soft sealing ones.

Equipment Selection:

The selection between soft and hard sealing ball valves depends on factors such as the process medium, temperature, and pressure. For applications with solid particles or high temperatures exceeding 200 degrees Celsius, hard sealing is preferred. For valves with a diameter larger than 50, consideration should also be given to the magnitude of the opening valve torque, with fixed hard-sealing ball valves being preferred when the torque is significant. Regardless of soft or hard sealing, both types can achieve a sealing level of Grade 6.

Conclusion:

In equipment selection, the choice between soft and hard sealing ball valves depends on various factors such as the process medium, temperature, pressure, and torque requirements. While hard sealing offers advantages in high-pressure and high-temperature environments, soft sealing may be preferred for certain applications due to its lower cost and suitability for specific media. Ultimately, the selection should be based on the specific needs and conditions of the application.

Structural Mechanism:

Hard sealing in high-pressure ball valves involves metal-to-metal sealing between the ball and the seat, requiring precision machining and typically used in high-pressure applications, usually above 35MPa. On the other hand, soft sealing involves sealing between metal and non-metal materials like nylon or polytetrafluoroethylene (PTFE), maintaining similar manufacturing standards.

Sealing Material:

Soft and hard sealing refer to the sealing material of the valve seat. Hard sealing utilizes precision-machined seat materials like stainless steel or copper to ensure accuracy in conjunction with the valve core (ball). In contrast, soft sealing involves non-metallic sealing materials embedded in the seat, offering lower requirements for machining precision due to the elasticity of the soft sealing material.

Manufacturing Process:

In complex environments such as those found in chemical and mechanical industries, where high temperatures, high pressures, and corrosive media are common, advancements in technology have allowed for the effective use of various materials and manufacturing processes, leading to the widespread adoption of hard-sealing ball valves.

Usage Conditions:

Soft sealing generally achieves high levels of sealing, while hard sealing can vary depending on requirements. Soft sealing requires fire prevention measures as the material may leak under high temperatures, whereas hard sealing doesn't face this issue. Hard sealing can typically withstand higher pressures than soft sealing, although soft sealing may not be suitable for certain corrosive media. Additionally, hard sealing valves are generally more expensive than soft sealing ones.

Equipment Selection:

The selection between soft and hard sealing ball valves depends on factors such as the process medium, temperature, and pressure. For applications with solid particles or high temperatures exceeding 200 degrees Celsius, hard sealing is preferred. For valves with a diameter larger than 50, consideration should also be given to the magnitude of the opening valve torque, with fixed hard-sealing ball valves being preferred when the torque is significant. Regardless of soft or hard sealing, both types can achieve a sealing level of Grade 6.

Conclusion:

In equipment selection, the choice between soft and hard sealing ball valves depends on various factors such as the process medium, temperature, pressure, and torque requirements. While hard sealing offers advantages in high-pressure and high-temperature environments, soft sealing may be preferred for certain applications due to its lower cost and suitability for specific media. Ultimately, the selection should be based on the specific needs and conditions of the application.

Next: Why Choose Forged Flanged Ball Valves?

Previous: What are Forged Steel Gate Valves and Their Industrial Applications?

News

About Us

Best Categories

Useful Links