What are Forged Steel Gate Valves and Their Industrial Applications?

What are Forged Steel Gate Valves and Their Industrial Applications?

Mar 21, 2024

In industrial settings, gate valves play a vital role in regulating the flow of fluids within specific areas, primarily focusing on pressure control. With diverse applications and user requirements, these valves are available in various sizes and types, including ball valves, butterfly valves, and globe valves. Depending on the specific needs of your operation, you may find yourself requiring one or more types of industrial gate valves to effectively manage your processes.

Forged steel gate valves are top-tier industrial valves crafted from a range of materials such as carbon steel and stainless steel. Engineered to endure extreme temperatures, harsh environments, and heavy impacts, they offer unparalleled resilience. These valves boast versatility in size and configuration, catering to diverse applications like water, wastewater, steam, and gas distribution.

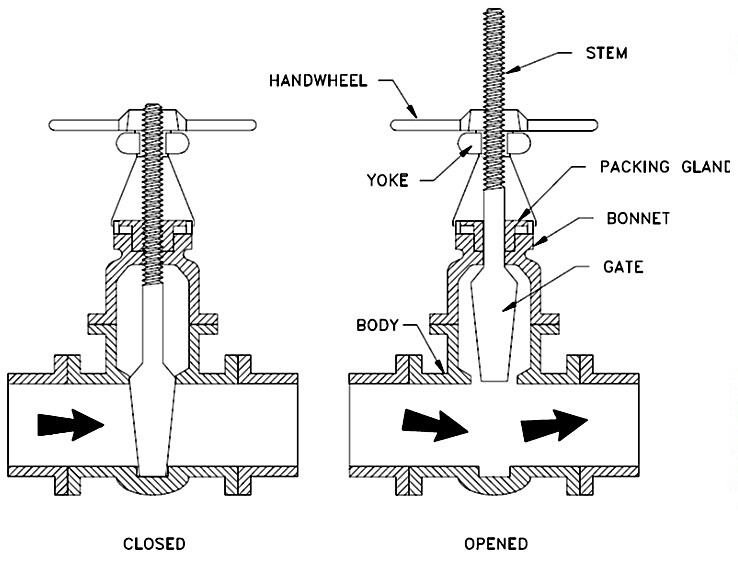

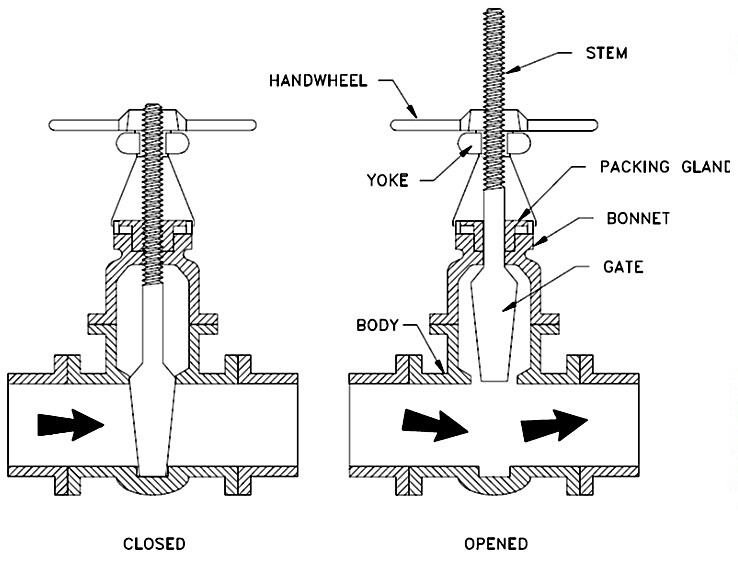

Available in manual and automatic variants, industrial forged steel gate valves maintain a consistent design across different sizes. They typically comprise a head fitting over the pipe end, an extending arm, and a handle for operation. Moreover, these valves can be tailored to specific requirements, including material composition, size, and shape, with options for additional features such as pressure relief mechanisms or specialized adaptations for challenging environments.

Forged steel gate valves find widespread application across various industries for controlling the flow of water, gas, and other substances. In manufacturing, these valves are employed in diverse settings, such as directing water flow within a plant or regulating water supply in facilities like garages or car washes. Additionally, industries like oil and gas extraction rely on forged steel gate valves to manage the flow of oil between different components of drilling rigs. Beyond these examples, numerous other sectors utilize these valves for their robust performance and reliability.

Forged steel gate valves hold significant importance in modern manufacturing, offering a myriad of benefits to manufacturers. Renowned for their lightweight construction, durability, and reliability, these valves excel in high-pressure environments, ensuring efficient operation and longevity.

Available in diverse styles such as one-way, double-acting, and butterfly, forged steel gate valves provide versatility in fluid flow control. One-way gates facilitate the regulation of high-pressure fluids in both directions, while double-acting gates enable simultaneous opening of two pressure points. Meanwhile, butterfly gates offer independent openings for different pressures, enhancing adaptability across various industrial settings.

Moreover, forged steel gate valves boast a competitive price point compared to alternative valve assemblies, making them an optimal choice for applications where cost-effectiveness is paramount.

With their suitability for use in diverse environments and applications, including oil and gas, food manufacturing, and wastewater treatment plants, forged steel gate valves emerge as indispensable components in industrial operations.

In conclusion, forged steel gate valves stand out as the preferred option for manufacturers seeking robust, durable, and reliable valves for their industrial applications. Their multitude of advantages, encompassing low weight, smooth operation, and enduring durability, coupled with a wide range of valve options, ensure seamless adaptation to specific application requirements.

Forged steel gate valves are top-tier industrial valves crafted from a range of materials such as carbon steel and stainless steel. Engineered to endure extreme temperatures, harsh environments, and heavy impacts, they offer unparalleled resilience. These valves boast versatility in size and configuration, catering to diverse applications like water, wastewater, steam, and gas distribution.

Available in manual and automatic variants, industrial forged steel gate valves maintain a consistent design across different sizes. They typically comprise a head fitting over the pipe end, an extending arm, and a handle for operation. Moreover, these valves can be tailored to specific requirements, including material composition, size, and shape, with options for additional features such as pressure relief mechanisms or specialized adaptations for challenging environments.

Forged steel gate valves find widespread application across various industries for controlling the flow of water, gas, and other substances. In manufacturing, these valves are employed in diverse settings, such as directing water flow within a plant or regulating water supply in facilities like garages or car washes. Additionally, industries like oil and gas extraction rely on forged steel gate valves to manage the flow of oil between different components of drilling rigs. Beyond these examples, numerous other sectors utilize these valves for their robust performance and reliability.

Forged steel gate valves hold significant importance in modern manufacturing, offering a myriad of benefits to manufacturers. Renowned for their lightweight construction, durability, and reliability, these valves excel in high-pressure environments, ensuring efficient operation and longevity.

Available in diverse styles such as one-way, double-acting, and butterfly, forged steel gate valves provide versatility in fluid flow control. One-way gates facilitate the regulation of high-pressure fluids in both directions, while double-acting gates enable simultaneous opening of two pressure points. Meanwhile, butterfly gates offer independent openings for different pressures, enhancing adaptability across various industrial settings.

Moreover, forged steel gate valves boast a competitive price point compared to alternative valve assemblies, making them an optimal choice for applications where cost-effectiveness is paramount.

With their suitability for use in diverse environments and applications, including oil and gas, food manufacturing, and wastewater treatment plants, forged steel gate valves emerge as indispensable components in industrial operations.

In conclusion, forged steel gate valves stand out as the preferred option for manufacturers seeking robust, durable, and reliable valves for their industrial applications. Their multitude of advantages, encompassing low weight, smooth operation, and enduring durability, coupled with a wide range of valve options, ensure seamless adaptation to specific application requirements.

Next: The Difference between Soft and Hard Sealing in High-Pressure Ball Valves

Previous: Precautions for Forged Steel Valves

News

About Us

Best Categories

Useful Links