Temperature Field Calculation & Thermo-solid Coupling Analysis of High-temperature Forged Gate Valves (Part One)

Temperature Field Calculation & Thermo-solid Coupling Analysis of High-temperature Forged Gate Valves (Part One)

Sep 30, 2021

Abstract

Given the design requirements for high-temperature forged steel gate valves, the virtual performance evaluation technology of gate valves is studied based on standard specifications and finite element analysis methods of the American Society of Mechanical Engineers (ASME). To ensure the safe and reliable operation of gate valves under high-temperature conditions, a method for calculating the temperature and stress field of high-temperature forged steel gate valves by using finite element software Ansys is proposed. First of all, the temperature and total stress field of high-temperature forged steel gate valves is quantitatively calculated and analyzed, and then the stress evaluation is completed and structural performance is analyzed and evaluated. The results show that the gate valve bonnet's cylinder height is sufficient; the design area of the heat dissipation plate is reasonable, and the pressure-bearing boundary components can meet the requirement for strength, which has good engineering practical value.

Gate valves are widely used in metallurgy, electric power, oil refining, petrochemical, natural gas and other pipelines. They can cut off or connect the medium in the pipeline. Common petrochemical gate valves have the characteristics of uniform wear of valve seats, small operating torque, and easy maintenance because of the particularity of environmental conditions and system operating conditions.

The working temperature of a high-temperature forged steel gate valve in a petrochemical project is as high as 816℃. In order to ensure the safe and reliable operation of the gate valve under high-temperature conditions, the design process must consider the requirements for heat transfer and mechanical strength. According to the design requirements for heat transfer, under high-temperature working conditions, the temperature at the bottom of the gate valve's stuffing box and handwheel must not be too high and must be controlled within the allowable range. In addition to ensuring that the high-temperature gate valve can withstand the stress caused by the mechanical load, the thermal stress caused by the thermal effect should also be considered to avoid insufficient fatigue strength and thermal fatigue for gate valves, affecting reliability. Therefore, in the research and development process of gate valves, accurate calculation of thermal load and its effects, and reasonable prediction of the structural performance of the gate valve under high-temperature conditions have become the key to the design. There are always hidden dangers for designing high-temperature gate valves with more complex structure by adopting conventional design methods due to the limitations of traditional design of formula methods. The finite element method is an effective method to solve the temperature field and stress field. This method of virtual product design and simulation without experiment or less experiment can not only reduce the product's development cycle, but also reduce the cost of development.

In this article, the finite element software Ansys is used to simulate the actual operating conditions of the gate valve. The temperature and total stress field of the high-temperature forged steel gate valve are calculated quantitatively and analyzed. Structural performance is analyzed and evaluated, achieving the purpose of guiding the design of key components of the gate valve.

1. The structure and requirements for high-temperature forged steel gate valves

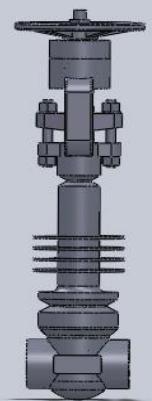

The total height of the high-temperature forged steel gate valve is 470 mm. The nominal diameters of the inlet and outlet are both 80 mm, and the maximum working pressure is 14.6MPa. The highest working temperature is 816°C, and the working pressure and torque data of handwheels under normal temperature and high-temperature conditions are shown in Table 1. Use the three-dimensional modeling software Solidworks to establish a three-dimensional solid model for the gate valve, including the valve body, extended cylinder bonnet (including the heat sink), bracket, handwheel, valve seat, valve stem, connecting bolt, packing assembly and necessary internal parts. The parts are assembled into the overall gate valve model in the software. In order to avoid stress concentration, sharp corners should be avoided when designing and modeling the valve body and bonnet cavity to ensure uniform stress distribution. The three-dimensional geometric solid model of the high-temperature forged steel gate valve is shown in Figure 1.

Table 1 Operating pressure and handwheel torque under various conditions

Given the design requirements for high-temperature forged steel gate valves, the virtual performance evaluation technology of gate valves is studied based on standard specifications and finite element analysis methods of the American Society of Mechanical Engineers (ASME). To ensure the safe and reliable operation of gate valves under high-temperature conditions, a method for calculating the temperature and stress field of high-temperature forged steel gate valves by using finite element software Ansys is proposed. First of all, the temperature and total stress field of high-temperature forged steel gate valves is quantitatively calculated and analyzed, and then the stress evaluation is completed and structural performance is analyzed and evaluated. The results show that the gate valve bonnet's cylinder height is sufficient; the design area of the heat dissipation plate is reasonable, and the pressure-bearing boundary components can meet the requirement for strength, which has good engineering practical value.

Gate valves are widely used in metallurgy, electric power, oil refining, petrochemical, natural gas and other pipelines. They can cut off or connect the medium in the pipeline. Common petrochemical gate valves have the characteristics of uniform wear of valve seats, small operating torque, and easy maintenance because of the particularity of environmental conditions and system operating conditions.

The working temperature of a high-temperature forged steel gate valve in a petrochemical project is as high as 816℃. In order to ensure the safe and reliable operation of the gate valve under high-temperature conditions, the design process must consider the requirements for heat transfer and mechanical strength. According to the design requirements for heat transfer, under high-temperature working conditions, the temperature at the bottom of the gate valve's stuffing box and handwheel must not be too high and must be controlled within the allowable range. In addition to ensuring that the high-temperature gate valve can withstand the stress caused by the mechanical load, the thermal stress caused by the thermal effect should also be considered to avoid insufficient fatigue strength and thermal fatigue for gate valves, affecting reliability. Therefore, in the research and development process of gate valves, accurate calculation of thermal load and its effects, and reasonable prediction of the structural performance of the gate valve under high-temperature conditions have become the key to the design. There are always hidden dangers for designing high-temperature gate valves with more complex structure by adopting conventional design methods due to the limitations of traditional design of formula methods. The finite element method is an effective method to solve the temperature field and stress field. This method of virtual product design and simulation without experiment or less experiment can not only reduce the product's development cycle, but also reduce the cost of development.

In this article, the finite element software Ansys is used to simulate the actual operating conditions of the gate valve. The temperature and total stress field of the high-temperature forged steel gate valve are calculated quantitatively and analyzed. Structural performance is analyzed and evaluated, achieving the purpose of guiding the design of key components of the gate valve.

1. The structure and requirements for high-temperature forged steel gate valves

The total height of the high-temperature forged steel gate valve is 470 mm. The nominal diameters of the inlet and outlet are both 80 mm, and the maximum working pressure is 14.6MPa. The highest working temperature is 816°C, and the working pressure and torque data of handwheels under normal temperature and high-temperature conditions are shown in Table 1. Use the three-dimensional modeling software Solidworks to establish a three-dimensional solid model for the gate valve, including the valve body, extended cylinder bonnet (including the heat sink), bracket, handwheel, valve seat, valve stem, connecting bolt, packing assembly and necessary internal parts. The parts are assembled into the overall gate valve model in the software. In order to avoid stress concentration, sharp corners should be avoided when designing and modeling the valve body and bonnet cavity to ensure uniform stress distribution. The three-dimensional geometric solid model of the high-temperature forged steel gate valve is shown in Figure 1.

Table 1 Operating pressure and handwheel torque under various conditions

| Operating conditions | Working pressure/MPa | Handwheel Torque/(N.m) |

| Room temperatures | 14.6 | 23.2 |

| High temperatures of 816℃ | 0.72 | 11.2 |

Figure 1 The three-dimensional solid model diagram of the gate valve

2. Evaluation requirements and acceptance criteria

As a pressure-bearing device, a gate valve is subjected to stress analysis and evaluation in accordance with the pressure vessel analysis and design method. See Table 2 for specific stress assessment criteria.

In Table 2, Pr is the partial primary film stress. Pp is the primary bending stress. Q is the secondary stress, and S is the maximum allowable stress. The material used for the valve body and bonnet is F304H. The yield strength of the material at room temperatures is 205MPa. The allowable stress S is 138MPa. The allowable stress of the valve body and bonnet material at a temperature of 816°C is 8.7MPa. The allowable stress is 26MPa at a temperature of 700°C.

Table 2 Stress evaluation criteria

| Working conditions | Load combination | Stress assessment limits |

| Normal temperature conditions | Design pressure plus handwheel torque plus bolt pre-tightening force | PL being less than and equal to 1.5S PL plus Pb being less than and equal to 1.5S |

| High temperature working conditions | Design pressure plus handwheel torque plus bolt pre-tightening force plus thermal effect | PL being less than and equal to 1.5S PL plus Pb being less than and equal to 1.5S PL plus Pb plus Q being less than and equal to 3S |

The design requires that the temperature of the bottom of the gate valve's stuffing box and outer circle of the handwheel should not be too high, and the temperature of the bottom of the gate valve stuffing box should not exceed 300°C; the temperature of the outer circle of the handwheel should not exceed 100°C. The excessive temperature of the stuffing box will affect the sealing performance of the valve, and too high temperatures of the outer circumference of the handwheel will affect the operability.

Previous: Research on Generalization of Forged Steel Hydrogenation Valve Bodies Based on the Finite Element

News

About Us

Best Categories

Useful Links