Design and Research of Forged Slab Gate Valves without Welding Seams

Design and Research of Forged Slab Gate Valves without Welding Seams

Aug 10, 2021

Forged slab gate valves without welding seams made from nickel alloy 625 with pressure of Class 900 and 15% of H2S content in the medium have advantages under conditions of high requirements and strong corrosion. They have good practicability and operability in practical applications, and bright prospects of the market promotion.

1. Overall structure

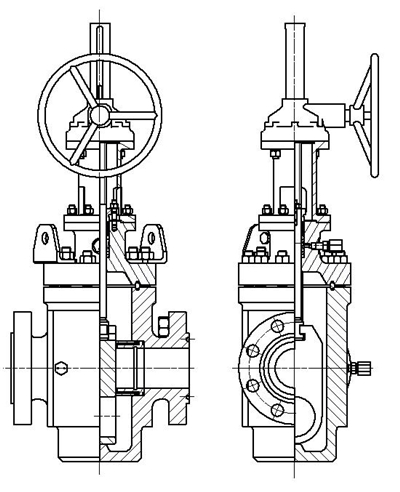

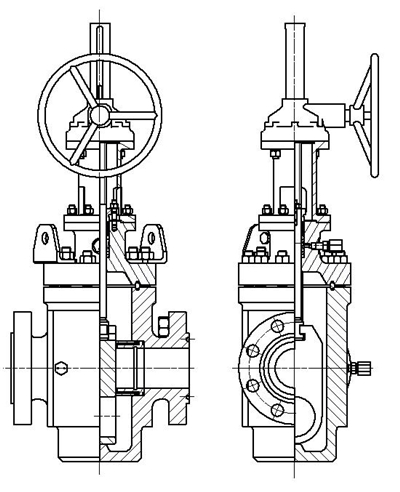

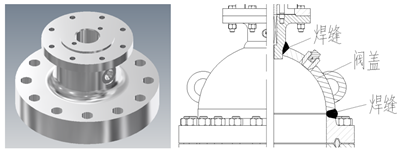

The main parts of the forged slab gate valve without welding seams, such as the valve body, bonnet, valve seat, gate plate and valve stem are forged as a whole and then machined (Figure 1). The shells are all made from forged steel, so the material's organization is uniform, compact, high-impact; the main structure is completely not welded to prevent outer leakages. The appearance is neat; the internal structure of the gate valve is compact, and the practicability is good. At the same time, the size deviation between the center of the flow channel and that of the valve body caused by welding and the thermal stress deformation of the valve body due to welding are avoided. The need for annealing heat treatment after welding to eliminate stress is not required. The structure comparison is shown in Figure 2.

Figure 1 Forged slab gate valves without welding seams

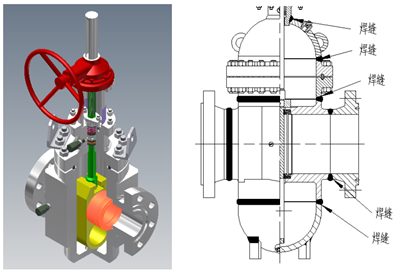

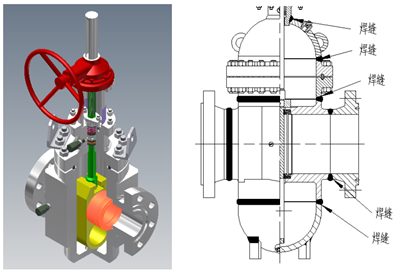

(a) Integrated forging structure without welding seams (b) Traditional welding structure

1. Overall structure

The main parts of the forged slab gate valve without welding seams, such as the valve body, bonnet, valve seat, gate plate and valve stem are forged as a whole and then machined (Figure 1). The shells are all made from forged steel, so the material's organization is uniform, compact, high-impact; the main structure is completely not welded to prevent outer leakages. The appearance is neat; the internal structure of the gate valve is compact, and the practicability is good. At the same time, the size deviation between the center of the flow channel and that of the valve body caused by welding and the thermal stress deformation of the valve body due to welding are avoided. The need for annealing heat treatment after welding to eliminate stress is not required. The structure comparison is shown in Figure 2.

Figure 1 Forged slab gate valves without welding seams

(a) Integrated forging structure without welding seams (b) Traditional welding structure

Figure 2 A comparison of integrated forging structure without welding seams and traditional welding structure

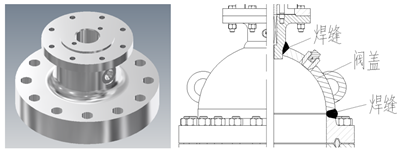

2. The structure of the valve bonnet

The valve bonnet is integrally forged and then formed by machining. The main body has no welding connection, which ensures the advantages of forged steel and avoids the deviation of the center's size of the bonnet caused by the welding connection and the thermal stress deformation of the bonnet due to welding. The annealing heat treatment after welding is not required. The structural comparison of the bonnet is shown in Figure 3.

2. The structure of the valve bonnet

The valve bonnet is integrally forged and then formed by machining. The main body has no welding connection, which ensures the advantages of forged steel and avoids the deviation of the center's size of the bonnet caused by the welding connection and the thermal stress deformation of the bonnet due to welding. The annealing heat treatment after welding is not required. The structural comparison of the bonnet is shown in Figure 3.

(a) Valve bonnets without welding seams (b) Traditional valve bonnets

Figure 3 A comparison of the structure of valve bonnets without welding seams and traditional valve bonnets

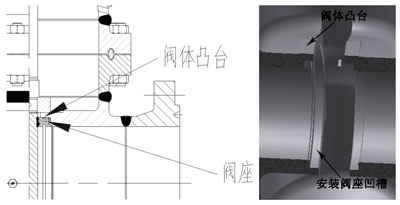

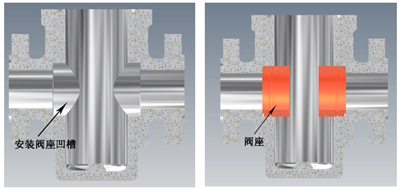

3. The installation of the valve seat

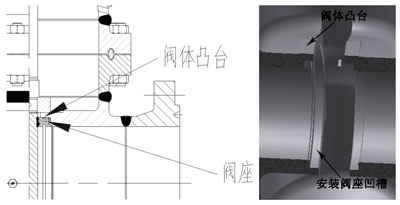

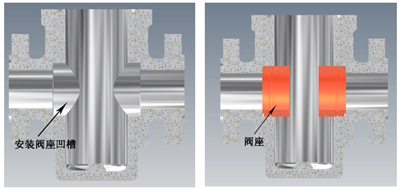

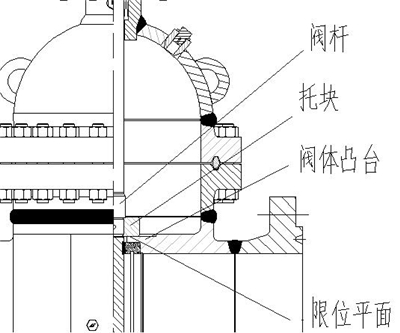

Compared with the traditional slab gate valve, the installation of the valve seat is different inside the valve body. The valve body of the traditional forged steel slab gate valve must be equipped with a boss where the valve seat is installed (Figure 4), and a groove for installing the valve seat is machined inside the boss. Check figure 5 for forged steel slab gate valves without welding seams. Grooves can be directly machined inside the valve body for the installation of the valve seat.

(a) The plane structure (b) The three-dimensional structure

Figure 4 The seat installation of traditional forged steel slab gate valves

(a) The installation of the valve seat’s groove (b) The valve seat

Figure 5 The installation of forged steel slab gate valve seats without welding seams

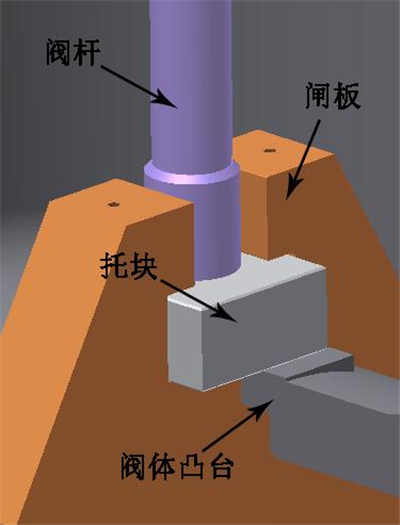

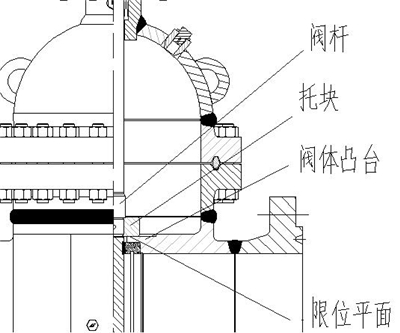

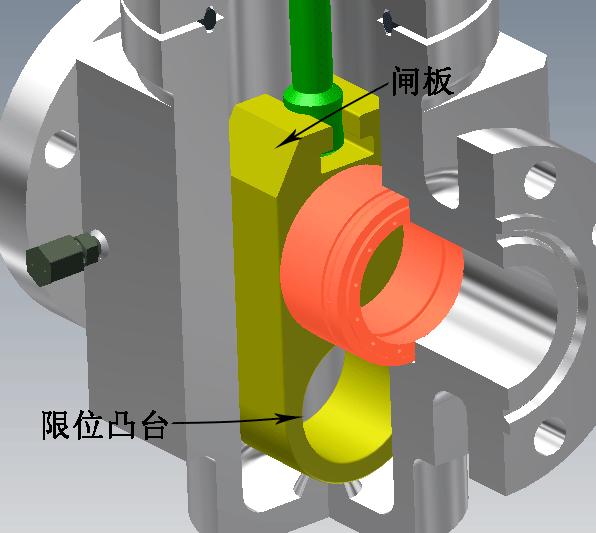

4. The connection mode of the valve stem and valve plate

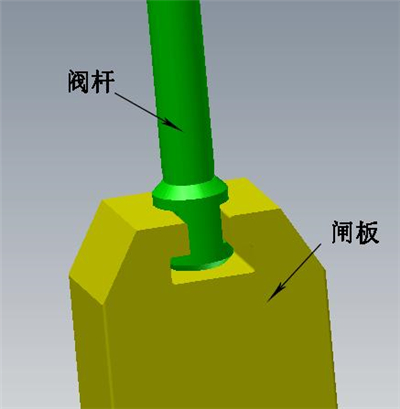

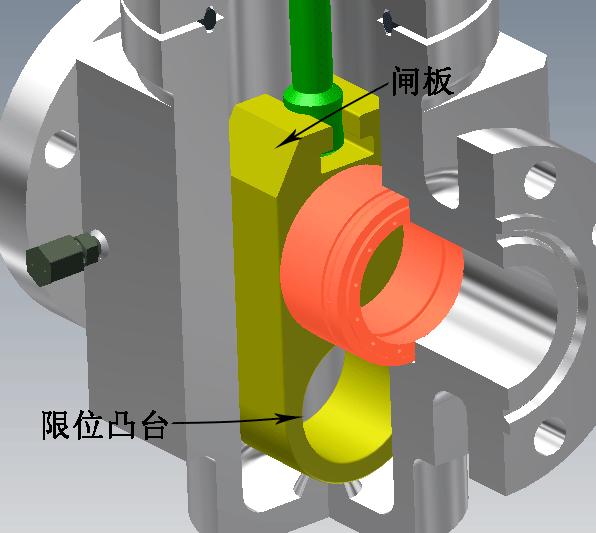

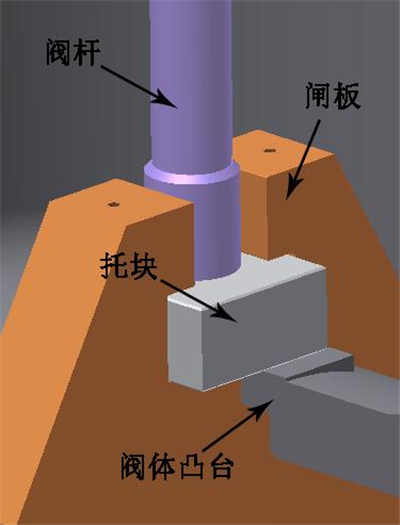

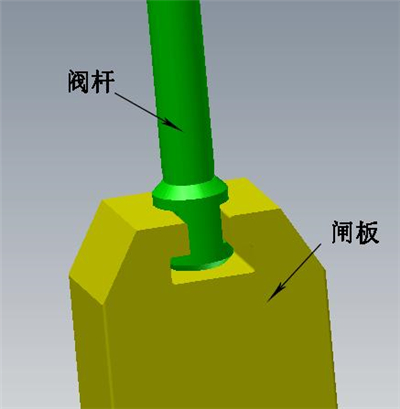

The connection between the valve stem and plate of slab gate valves without welding seams is different from that of traditional slab gate valves. The forged steel slab gate valve without welding seams is directly provided with a groove on the valve stem. The groove drives the plate to move up and down, and the valve is fully opened with the boss at the bottom valve body and the plate to achieve the purpose of the mechanical limit of the full opening of the valve. The comparison of the connection between the valve stem and plate for traditional slab gate valves and slab gate valves without welding seams is shown in Figures 6 to 9.

Figure 6 The traditional connection of the valve stem and plate

Figure 7 The connection of the valve stem and plate of a slab gate valve without welding seams

Figure 8 Traditional forged steel slab gate valves

Figure 9 Forged steel slab gate valves without welding seams

Compared with the traditional slab gate valve, the forged steel slab gate valve without welding seams has a great improvement in the structural design, manufacturing and assembly, which can better and more reasonably utilize the characteristics of forged steel, reduce consumption of materials, improve manufacturability and overall performance, and prolong the service life.

3. The installation of the valve seat

Compared with the traditional slab gate valve, the installation of the valve seat is different inside the valve body. The valve body of the traditional forged steel slab gate valve must be equipped with a boss where the valve seat is installed (Figure 4), and a groove for installing the valve seat is machined inside the boss. Check figure 5 for forged steel slab gate valves without welding seams. Grooves can be directly machined inside the valve body for the installation of the valve seat.

(a) The plane structure (b) The three-dimensional structure

Figure 4 The seat installation of traditional forged steel slab gate valves

(a) The installation of the valve seat’s groove (b) The valve seat

Figure 5 The installation of forged steel slab gate valve seats without welding seams

4. The connection mode of the valve stem and valve plate

The connection between the valve stem and plate of slab gate valves without welding seams is different from that of traditional slab gate valves. The forged steel slab gate valve without welding seams is directly provided with a groove on the valve stem. The groove drives the plate to move up and down, and the valve is fully opened with the boss at the bottom valve body and the plate to achieve the purpose of the mechanical limit of the full opening of the valve. The comparison of the connection between the valve stem and plate for traditional slab gate valves and slab gate valves without welding seams is shown in Figures 6 to 9.

Figure 6 The traditional connection of the valve stem and plate

Figure 7 The connection of the valve stem and plate of a slab gate valve without welding seams

Figure 8 Traditional forged steel slab gate valves

Figure 9 Forged steel slab gate valves without welding seams

Compared with the traditional slab gate valve, the forged steel slab gate valve without welding seams has a great improvement in the structural design, manufacturing and assembly, which can better and more reasonably utilize the characteristics of forged steel, reduce consumption of materials, improve manufacturability and overall performance, and prolong the service life.

Next: Research on Generalization of Forged Steel Hydrogenation Valve Bodies Based on the Finite Element

Previous: An Introduction to a Forged Steel Ball Valve

News

About Us

Best Categories

Useful Links