Control Systems of ARM Automatic Forged Steel Ball Valve Core Lathes (Part One)

Control Systems of ARM Automatic Forged Steel Ball Valve Core Lathes (Part One)

Jun 30, 2022

Abstract:The research and development of forged steel ball valve core automatic lathes and control systems include the mechanical structure of the automatic lathe, its electrical and hydraulic drive devices, and the electrical control system of the automatic lathe. The mechanical structure and its driving device include frames, main shafts and motor driving devices, turntables and servo driving devices, feeding and unfeeding and hydraulic driving devices. The electrical control system includes logic signal input and output, analog signal input, PWM output, real-time clock, embedded controllers supporting CAN, USB, RS485, RS232, MODBUS and other communication protocols to facilitate communication with other systems such as industrial control panels. The embedded signal acquisition and display system based on the ARM Cortex M3 core collects the sensors of various parts of the lathe and the user input and output communication interface. The CAN bus is used to connect each control node, user communication node, sensor network and management PC to realize flexible and unified automatic control and realize data statistics and production management through the PC software. Forged steel ball valve core automatic lathes and control systems are widely used in all hard-sealed and soft-sealed ball valve manufacturers, which help to improve the production efficiency of enterprises and improve the quality of products.

In recent years, with the development of computer technology, communication technology and control technology, the traditional industrial control field is undergoing an unprecedented change. Networked control has become a development direction of industrial control systems based on the wide application of embedded technology and fieldbus. In the production site of a manufacturing enterprise, a lot of equipment is distributed in the workshop, many of which are operated completely by manual control; the statistics of production information rely on manual statistics, and the production efficiency and production technology level are very low. Many labor-intensive production industries have begun to use advanced electronic information technology to equip and modify traditional production equipment, and use advanced automatic control methods to replace the original manual operations. Fieldbus technology emerges to adapt to the development of modern industrial automation. The field bus introduces the concept of network communication, network control and management into the field of industrial control, interconnects the control equipment at the bottom of the automation with the server, and realizes the network control of the production process monitoring. The field bus communication protocol is simple and easy to implement, and has broad development prospects in the industrial field.

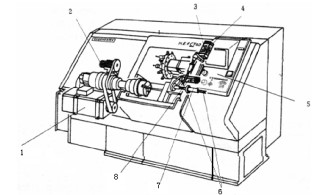

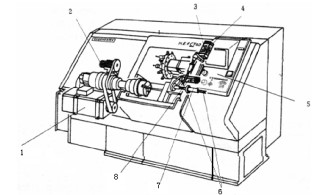

The CNC machining system is a method of digital signals to control the movement of the machine and the processing process. The core of CNC system is industrial computing. Usually, the numerical control system includes numerical control unit (NCU), man-machine communication, servo systems, programmable logic controller (PLC) and other parts. The most typical application of CNC systems is CNC machine tools, such as CNC lathes, CNC milling machines, CNC boring machines, CNC grinding machines, CNC drilling machines, etc., as well as some CNC combined machine tools and special machine tools. If a tool magazine, an accessory library and an automatic tool change accessory device are added on this basis to realize one machine with multiple functions, it is called a CNC machining center.

The competition in the machinery manufacturing industry in the 21st century is essentially the competition in numerical control technology. China started the research on the development of numerical control systems in 1958, and successfully developed a transistor numerical control system in 1966, and used the prototype for production. Some varieties have been produced in small batches, such as wire cutting machines, non-circular gear machines, and the integrated circuit numerical control system was successfully developed in 1972. Since the 1980s, China has introduced CNC manufacturing technology from Japan and Germany, which has made a qualitative leap in China's CNC technology, and developed a number of medium and high-end CNC systems with independent intellectual property rights.

A ball valve is a device used to change the pipeline section and the flow direction of the medium, and to control the pressure, flow and temperature of the conveyed medium. The ball valve uses the action of fluid pressure, elastic element force or pre-pressure to make the sealing pair (balls and valve seats) abut, contact or embed each other to reduce or eliminate the gap between the sealing surfaces and achieve a sealed contact seal. The performance of the sealing pair of the metal-sealed ball valve is mainly affected by the roundness of the ball and the roughness of the sealing surface between the ball and the valve seat. The roundness of the sphere affects the fitness between the sphere and the valve seat. If the fitness is good, the resistance of the fluid moving along the sealing surface will be increased, thereby improving the sealing. Roughness also has a great effect on sealing. When the roughness is high and the specific pressure is small, the leakage increases. When the specific pressure is great, the microscopic serrated peaks on the sealing surface are deformed under pressure, and the effect of roughness on the leakage is significantly reduced. If the deviation of the surface roughness of the sealing pair and sphere is great, the specific pressure required to ensure the sealing is great, and the residual deformation also becomes great.

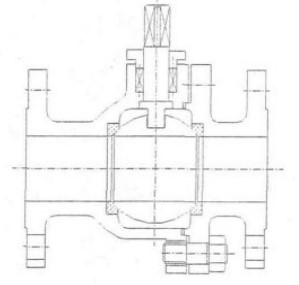

The ball valve uses the ball as the closing part. The ball can be rotated by 90° with the help of a handle or other driving devices, so that the through hole of the ball is coincide with or perpendicular to the centerline of the valve body channel, and the full opening or closing can be realized. The ball valve can be divided into floating ball valves and trunnion ball valves, and their structure is shown in Figure 1 and Figure 2. The ball of the floating ball valve is not supported by a support shaft, and only relies on two valve seats to support it. The valve stem is movably connected to the ball, and the ball is floating. When the valve is closed, the force generated by the fluid pressure on the ball is all transmitted to the valve seat. The greater the fluid pressure is, the easier the sealing of the floating ball valve becomes. However, when the diameter increases, the dead weight of the ball also increases, and the uneven pressure distribution on the valve seat caused by the dead weight also increases. Therefore, the diameter of the floating ball valve is limited to a certain extent, and its diameter is generally not greater than 200mm. Floating ball valves are widely used in industrial and civil fields due to their simple structure, convenient manufacture and low costs.

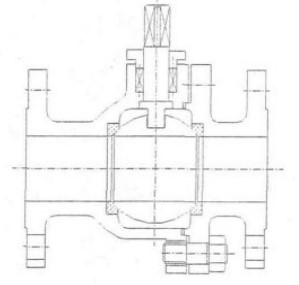

The ball of the trunnion ball valve is connected with the upper and lower shafts as a whole, and can freely rotate along the axis perpendicular to the valve channel, but cannot move along the channel axis. When the trunnion ball valve is working, the force generated by the fluid pressure on the ball is all transmitted to the valve body through the upper and lower shafts, and the ball will not move to the back seat of the valve, resulting in the valve seat not bearing excessive force, which is suitable for high pressure and large diameters.

Figure 1 The schematic diagram of the floating ball valve

Figure 2 The schematic diagram of the trunnion ball valve

In recent years, with the development of computer technology, communication technology and control technology, the traditional industrial control field is undergoing an unprecedented change. Networked control has become a development direction of industrial control systems based on the wide application of embedded technology and fieldbus. In the production site of a manufacturing enterprise, a lot of equipment is distributed in the workshop, many of which are operated completely by manual control; the statistics of production information rely on manual statistics, and the production efficiency and production technology level are very low. Many labor-intensive production industries have begun to use advanced electronic information technology to equip and modify traditional production equipment, and use advanced automatic control methods to replace the original manual operations. Fieldbus technology emerges to adapt to the development of modern industrial automation. The field bus introduces the concept of network communication, network control and management into the field of industrial control, interconnects the control equipment at the bottom of the automation with the server, and realizes the network control of the production process monitoring. The field bus communication protocol is simple and easy to implement, and has broad development prospects in the industrial field.

The CNC machining system is a method of digital signals to control the movement of the machine and the processing process. The core of CNC system is industrial computing. Usually, the numerical control system includes numerical control unit (NCU), man-machine communication, servo systems, programmable logic controller (PLC) and other parts. The most typical application of CNC systems is CNC machine tools, such as CNC lathes, CNC milling machines, CNC boring machines, CNC grinding machines, CNC drilling machines, etc., as well as some CNC combined machine tools and special machine tools. If a tool magazine, an accessory library and an automatic tool change accessory device are added on this basis to realize one machine with multiple functions, it is called a CNC machining center.

The competition in the machinery manufacturing industry in the 21st century is essentially the competition in numerical control technology. China started the research on the development of numerical control systems in 1958, and successfully developed a transistor numerical control system in 1966, and used the prototype for production. Some varieties have been produced in small batches, such as wire cutting machines, non-circular gear machines, and the integrated circuit numerical control system was successfully developed in 1972. Since the 1980s, China has introduced CNC manufacturing technology from Japan and Germany, which has made a qualitative leap in China's CNC technology, and developed a number of medium and high-end CNC systems with independent intellectual property rights.

A ball valve is a device used to change the pipeline section and the flow direction of the medium, and to control the pressure, flow and temperature of the conveyed medium. The ball valve uses the action of fluid pressure, elastic element force or pre-pressure to make the sealing pair (balls and valve seats) abut, contact or embed each other to reduce or eliminate the gap between the sealing surfaces and achieve a sealed contact seal. The performance of the sealing pair of the metal-sealed ball valve is mainly affected by the roundness of the ball and the roughness of the sealing surface between the ball and the valve seat. The roundness of the sphere affects the fitness between the sphere and the valve seat. If the fitness is good, the resistance of the fluid moving along the sealing surface will be increased, thereby improving the sealing. Roughness also has a great effect on sealing. When the roughness is high and the specific pressure is small, the leakage increases. When the specific pressure is great, the microscopic serrated peaks on the sealing surface are deformed under pressure, and the effect of roughness on the leakage is significantly reduced. If the deviation of the surface roughness of the sealing pair and sphere is great, the specific pressure required to ensure the sealing is great, and the residual deformation also becomes great.

The ball valve uses the ball as the closing part. The ball can be rotated by 90° with the help of a handle or other driving devices, so that the through hole of the ball is coincide with or perpendicular to the centerline of the valve body channel, and the full opening or closing can be realized. The ball valve can be divided into floating ball valves and trunnion ball valves, and their structure is shown in Figure 1 and Figure 2. The ball of the floating ball valve is not supported by a support shaft, and only relies on two valve seats to support it. The valve stem is movably connected to the ball, and the ball is floating. When the valve is closed, the force generated by the fluid pressure on the ball is all transmitted to the valve seat. The greater the fluid pressure is, the easier the sealing of the floating ball valve becomes. However, when the diameter increases, the dead weight of the ball also increases, and the uneven pressure distribution on the valve seat caused by the dead weight also increases. Therefore, the diameter of the floating ball valve is limited to a certain extent, and its diameter is generally not greater than 200mm. Floating ball valves are widely used in industrial and civil fields due to their simple structure, convenient manufacture and low costs.

The ball of the trunnion ball valve is connected with the upper and lower shafts as a whole, and can freely rotate along the axis perpendicular to the valve channel, but cannot move along the channel axis. When the trunnion ball valve is working, the force generated by the fluid pressure on the ball is all transmitted to the valve body through the upper and lower shafts, and the ball will not move to the back seat of the valve, resulting in the valve seat not bearing excessive force, which is suitable for high pressure and large diameters.

Figure 1 The schematic diagram of the floating ball valve

Figure 2 The schematic diagram of the trunnion ball valve

Next: Control Systems of ARM Automatic Forged Steel Ball Valve Core Lathes (Part Two)

Previous: High-pressure Cryogenic Large-diameter Three-piece Forged Ball Valves

News

About Us

Best Categories

Useful Links