Structural Design of Hydrogenation Valve Bodies

Structural Design of Hydrogenation Valve Bodies

Feb 28, 2023

The hydrogenation valve is a dedicated valve used in flammable and explosive occasions containing industrial hydrogen in the medium. The current petrochemical industry uses imported high-pressure hydrogenation valves in China based on the high risk of hydrogenation valves. To speed up the process of domestic hydrogenation valves and ensure the quality of hydrogenation valves, the structural design of the key parts of hydrogenation valves such as the valve body is particularly necessary. Taking a gate valve as an example, according to API 600 and other standards of the American Petroleum Institute and the requirements of customers such as Israel Petroleum Company, the structural design scheme of the valve body of the hydrogenation valve is proposed. Given the complexity of the influence of valve body material, flow channel form and integral forging structure on the quality of the valve body. Use SolidWorks to establish a three-dimensional solid model of the valve body based on the complex influence of valve body material, flow channel form and integral forging structure on quality. The boundary conditions of the valve body at maximum working conditions are given. Use the finite element analysis software MSC. Patran to perform an analysis for strength. The force and deformation of the valve body in various directions are obtained. The maximum stress part of the valve body is obtained and the rationality of the design of the valve body parts is verified.

1. The structure design of the valve body

1.1 Basic parameters

The technical parameters of the gate valve are as follows:

Nominal diameter: 8 inches

Nominal pressure: 1 500LB, or 25MPa

Applicable temperatures: -29°C to + 427°C

1.2 Materials and heat treatment of valve bodies

To meet hydrogen corrosion, choose the appropriate valve body material for the corrosion rate of various steel materials, such as WC6 (F11), WC9 (F22), F32l, F304 and A105N according to the high-temperature HzS+H in the curve. According to ASME B16.34 and the requirements of the customer’s order, the valve of the hydrogenation unit is generally made from ASTM A105N, F22 and F321. The main chemical composition of the A105N is that C is less than and equal to 0.23, P 0.035 and S 0.025. The heat treatment state is normalizing. The heat treatment state of F321 is solid solution plus normalizing treatment at temperatures of 850 to 870°C. F22 forgings shall be ASTM A182 F22 Class 3; the tensile strength shall not exceed 690MPa, and the heat treatment shall be normalizing plus tempering at 730°C.

1.3 The structure of the valve body

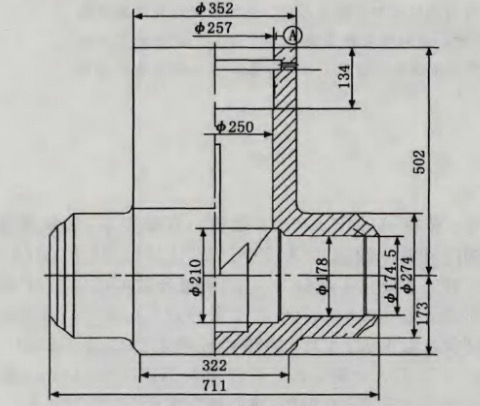

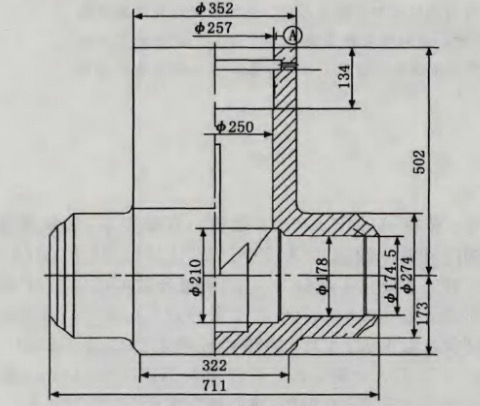

The valve body adopts an integral forging structure with a compact structure and good surface. The flow channel of the valve body adopts a full-bore design, and the flow channel aperture is the same as the nominal diameter of the valve. The design of structural dimensions such as wall thickness of valve bodies, flanges of valve bodies, and structural length is based on API 600 “Steel gate valves-flanged or butt-welded ends, bolted bonnets” and ASME B16.34 "Valves-flanged ends, threaded ends and butt welded ends" and other standards. The diagram of parts of the valve body is shown in Figure 1.

Figure 1 The diagram of valve body parts

1. The structure design of the valve body

1.1 Basic parameters

The technical parameters of the gate valve are as follows:

Nominal diameter: 8 inches

Nominal pressure: 1 500LB, or 25MPa

Applicable temperatures: -29°C to + 427°C

1.2 Materials and heat treatment of valve bodies

To meet hydrogen corrosion, choose the appropriate valve body material for the corrosion rate of various steel materials, such as WC6 (F11), WC9 (F22), F32l, F304 and A105N according to the high-temperature HzS+H in the curve. According to ASME B16.34 and the requirements of the customer’s order, the valve of the hydrogenation unit is generally made from ASTM A105N, F22 and F321. The main chemical composition of the A105N is that C is less than and equal to 0.23, P 0.035 and S 0.025. The heat treatment state is normalizing. The heat treatment state of F321 is solid solution plus normalizing treatment at temperatures of 850 to 870°C. F22 forgings shall be ASTM A182 F22 Class 3; the tensile strength shall not exceed 690MPa, and the heat treatment shall be normalizing plus tempering at 730°C.

1.3 The structure of the valve body

The valve body adopts an integral forging structure with a compact structure and good surface. The flow channel of the valve body adopts a full-bore design, and the flow channel aperture is the same as the nominal diameter of the valve. The design of structural dimensions such as wall thickness of valve bodies, flanges of valve bodies, and structural length is based on API 600 “Steel gate valves-flanged or butt-welded ends, bolted bonnets” and ASME B16.34 "Valves-flanged ends, threaded ends and butt welded ends" and other standards. The diagram of parts of the valve body is shown in Figure 1.

Figure 1 The diagram of valve body parts

Next: Analysis of Strength of Finite Element Model of Valve Bodies

Previous: Design of two-piece forged titanium ball valves with small diameters

News

About Us

Best Categories

Useful Links