Structural Characteristics of Forged Steel High Pressure Metal Sealed Ball Valves

Structural Characteristics of Forged Steel High Pressure Metal Sealed Ball Valves

Jan 13, 2021

1. Overviews

At present, the traditional ball valves used in China are generally cast steel low temperature and low-pressure soft seal ball valves, which are difficult to adapt to the harsh medium conditions of high temperature and pressure granular sand slurry in special pipelines, valve leakages and jamming due to sealing materials being not resistant to high temperature or sealing surfaces being damaged. The forged steel high-pressure metal sealed ball valve adopts the new technology, process and standard as well as three pieces forged steel trunnion mounted full bored structure, and has a beautiful appearance. In order to prevent the stress concentration of the ball valve, the main structure of the ball valve and cross-section being perpendicular to the valve channel axis along the valve seat are divided into three parts. The whole valve is symmetrical along the center axis of the valve stem. The accurate ball center position of the valve stem component under high pressure ensures good operation performance of the valve. The contact surface of the ball core and valve seat must be treated by a special process, and their surface hardness will reach 45 to 65HRC after treatment, which meet the requirements for high temperature and high pressure applications in the valve industry with operating temperatures up to 425°C, pressure above 10.0MPa and nominal diameters below 600mm. This super wear resistant ball valve cuts off, distributes and changes the flow direction of the medium in the valve pipeline.

2. Analysis of structural characteristics

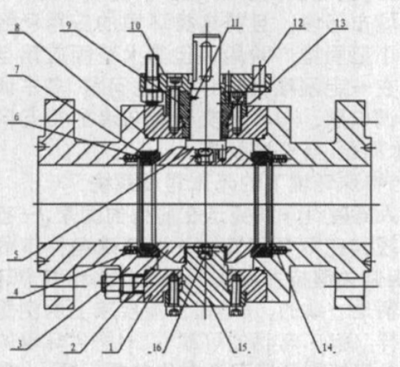

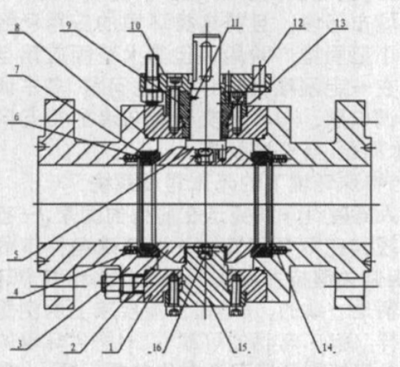

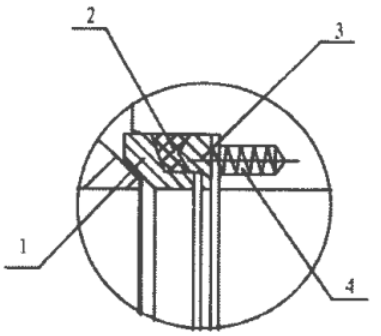

2.1 The main components of the forged steel high-pressure metal sealed ball valve are shown in the structural diagram of Figure 1: intermediate bodies, ball cores, left and right bodies, valve seats, valve stems, valve seat support rings and elastic end pads, packing, electrostatic springs, sliding bearings, valve stem greases, thrust springs, bottom shafts and central body drain plugs, etc.

Figure 1 The structural diagram

2.2 The contact surface of the ball core and valve seat constitutes a high temperature resistant and super wear resistant sealing pair. The valve seat sealing pair is designed as a separate body to compensate for the impact of expansion caused by heat and contraction caused by cold on the valve and ensure the long-term reliability of the valve seal. The spring force of the thrust spring at the bottom of the valve seat support ring pushes the valve seat gasket to produce benign sealing performance.

2.3 The valve stem adopts a bottom mounted type with an inverted sealing structure to ensure reliable sealing at the packing and prevent the valve stem from falling.

2.4 There are springs and spring electrostatic pins at the contact surface between the lower end of the valve stem and the ball core as well as the upper end of the valve stem and the valve bonnet to ensure that the ball core, valve stem and valve bonnet form an electrostatic passage.

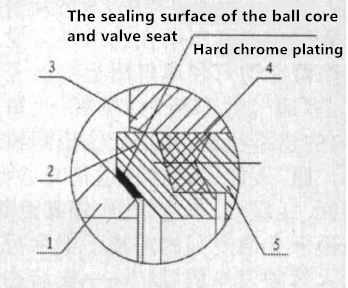

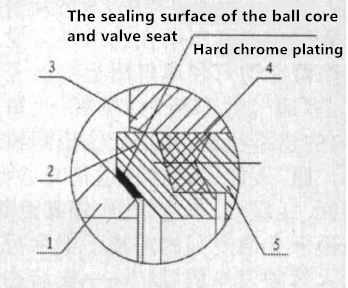

2.5 The intermediate body and left and right body ends are equipped with high performance sealing rings and elastic end face pads of polymer structure flexible graphite. Figure 2 is the end face sealing form, which has a double sealing effect.

2. Analysis of structural characteristics

2.1 The main components of the forged steel high-pressure metal sealed ball valve are shown in the structural diagram of Figure 1: intermediate bodies, ball cores, left and right bodies, valve seats, valve stems, valve seat support rings and elastic end pads, packing, electrostatic springs, sliding bearings, valve stem greases, thrust springs, bottom shafts and central body drain plugs, etc.

Figure 1 The structural diagram

2.2 The contact surface of the ball core and valve seat constitutes a high temperature resistant and super wear resistant sealing pair. The valve seat sealing pair is designed as a separate body to compensate for the impact of expansion caused by heat and contraction caused by cold on the valve and ensure the long-term reliability of the valve seal. The spring force of the thrust spring at the bottom of the valve seat support ring pushes the valve seat gasket to produce benign sealing performance.

2.3 The valve stem adopts a bottom mounted type with an inverted sealing structure to ensure reliable sealing at the packing and prevent the valve stem from falling.

2.4 There are springs and spring electrostatic pins at the contact surface between the lower end of the valve stem and the ball core as well as the upper end of the valve stem and the valve bonnet to ensure that the ball core, valve stem and valve bonnet form an electrostatic passage.

2.5 The intermediate body and left and right body ends are equipped with high performance sealing rings and elastic end face pads of polymer structure flexible graphite. Figure 2 is the end face sealing form, which has a double sealing effect.

1. Valve cores 2. Valve seats 3. Left and right bodies 4. Valve seat gaskets 5. Valve seat sport rings

2.6 The valve bonnet and seal part of the valve stem adopt high quality wedge packing and O-ring seal double seal protection. The packing has good self-sealing performance, reliable sealing, and is especially suitable for gas media.

2.7 There is a sliding bearing for the contact part between the bottom shaft and ball core as well as the bottom end of the valve bonnet and stem to reduce the friction coefficient and operating torque, and facilitate the opening and closing of the valve.

2.8 The bottom shaft is directly fixed in the ball core to prevent the acting force generated by the medium from shifting the ball core under high pressure and effectively avoid leakage.

2.9 In order to regularly discharge and clean impurities in the middle cavity, upper and lower ends of intermediate bodies are provided with a middle body drain plug.

Figure 3 The valve seat component diagram

1. Valve seats 2. Valve seat gaskets 3. Valve seat supports 4. Compression springs

3. Design of main components

Whether the design of the valve seat is reasonable will directly affect the sealing performance and service life of the forged ball valve. The core seal of the ball valve should be composed of the valve seat component such as the valve seat, valve seat gasket, valve seat support ring and compression spring as shown in Figure 3. In order to make the metal valve seat resilient under the thrust of media, the bottom of the valve seat is designed into a bevel shape to facilitate the insertion of the seat gasket. Because working pressure of the ball valve is above 10.0MPa, a dovetail groove is designed at the end of the seat gasket for the seat to be inserted into it. A spring structure is designed for the bottom of the valve seat support ring. Under the action of the spring and medium pressure, the spherical part of the metal valve seat and sphere core form a metal to metal contact to ensure good two-way sealing performance of the inlet and outlet. This new creative design improves internal quality of products and enhances the stability and reliability of the valve.

4. Special process requirements

When the ball valve is opened and closed during use, the sealing surface is worn to different degrees due to the erosion, corrosion and accumulation of media, resulting in serious valve leakages. At this time, the sealing pair is required to be hard chrome plated. According to different materials of sphere cores, surface hardening treatments such as chrome plating, surfacing corrosion resistant layer, plasma nitriding and supersonic spraying metal particles should be used. At the same time, the valve seat must be treated with a corresponding special process. Stellite alloys, corrosion resistant layers or plasma nitriding can be welded on the sealing surface of the valve seat. They should be matched and ground with the sphere core to form an uninterrupted sealing strip, achieving the purpose of zero leakages. This important new process technology has eliminated the defect of constant replacement of valves due to the damage of the valve seat sealing, realized the use requirements under special working conditions of erosion resistance, corrosion resistance, high temperature resistance and high pressure resistance, made the valve pipeline system operate normally and extended the service life of the valve.

5. Conclusion

The design and manufacture, flange connection size and structural length of the new ultra normal wear resistant forged steel high-pressure metal sealed ball valve with good hardness respectively adopt the provisions of American standards ANSI B16.34, B16.5 and B16.10. All parts are forgings. The main parts such as left & right bodies as well as valve bonnets are made from A105 or A182, and ball cores A105+ENP. The advent of this new product has filled a gap in the domestic valve industry and reached the international advanced level of similar products. It is currently widely used in petroleum, chemical, light industry, metallurgy, paper, mining, electric power, military facilities and sulfide long-distance natural gas pipelines with hydrogen sulfide, many impurities and serious corrosion.

Next: Design and Forging Process of Forged Steel High Pressure Ball Valve Bodies

Previous: Water-cooled High Temperature Forged Steel Valves

News

About Us

Best Categories

Useful Links