Optimization of Surfacing Welding of Forged Steel Valve Bodies (Part One)

Optimization of Surfacing Welding of Forged Steel Valve Bodies (Part One)

Mar 19, 2021

Abstract: Given that gas holes, cracks and other defects often appear in the surfacing of the sealing surface of the small-diameter forged steel valve body, we focus on the current, voltage and surfacing surface height to analyze the influences of their changes on the quality of the surfacing surface. Find out the law of defects, hardness and structure composition with parameters by analyzing surface observation, hardness inspection and metallographic tests, and finally optimize and find the most suitable process parameters for surfacing welding.

As traditional and efficient surface engineering technology, the surfacing technology for valves has been developed in recent years. Take the sealing surface's surfacing welding of the body of forged steel valves as the research object in this article. The causes of common defects of sealing surfaces of valves such as gas holes and cracks are studied. The optimal parameters are finally selected to reduce the defects of the sealing surface and make the performance of the sealing surface reach the best mechanical properties based on the influences of different currents, voltages and surfacing surface thicknesses on hardness of sealing surfaces and organization.

1. Optimization tests of surfacing process parameters of sealing surfaces

1.1 Testing materials and equipment

(1) Testing materials: 20 steel forgings are adopted for the test and the valve body of simulation test-piece is surfaced with Stellite 6.

(2) Testing equipment: The welding equipment used for surfacing is the DC arc welding machine ZXT-400B.

1.2 Welding samples

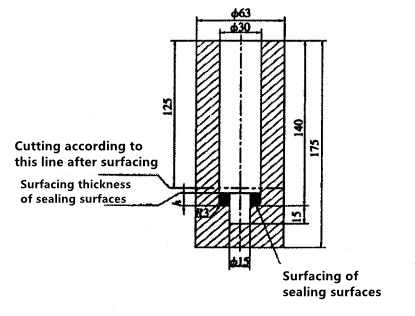

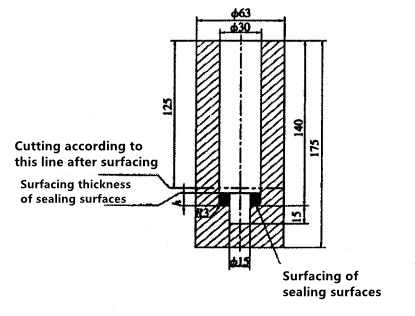

A total of 16 welding samples (Figure 1) were used with different heights of surfacing welding under different parameters.

Figure 1 Welding samples

1.3 Pre-welding preparation and post-welding treatment

(1) Preheating: Preheat the sample at a temperature of 500 to 550℃ for 1 to 2 hours by an electric furnace.

(2) Welding rods: Use a Stellite 6 welding rod with a thickness of 4.0 mm; baking temperatures are between 150 and 200℃ and the baking time is from 1 to 1.5 hours.

(3) Post-welding heat treatment: Conduct the post-welding heat treatment around 650℃ for 1.5 to 2 hours by an electric furnace.

1.4 Testing methods

When the welding current, voltage and height of the surfacing surface are different, the samples are surfaced. See the Table 1 for surfacing process parameters.

Table 1 Surfacing process parameters

As traditional and efficient surface engineering technology, the surfacing technology for valves has been developed in recent years. Take the sealing surface's surfacing welding of the body of forged steel valves as the research object in this article. The causes of common defects of sealing surfaces of valves such as gas holes and cracks are studied. The optimal parameters are finally selected to reduce the defects of the sealing surface and make the performance of the sealing surface reach the best mechanical properties based on the influences of different currents, voltages and surfacing surface thicknesses on hardness of sealing surfaces and organization.

1. Optimization tests of surfacing process parameters of sealing surfaces

1.1 Testing materials and equipment

(1) Testing materials: 20 steel forgings are adopted for the test and the valve body of simulation test-piece is surfaced with Stellite 6.

(2) Testing equipment: The welding equipment used for surfacing is the DC arc welding machine ZXT-400B.

1.2 Welding samples

A total of 16 welding samples (Figure 1) were used with different heights of surfacing welding under different parameters.

Figure 1 Welding samples

1.3 Pre-welding preparation and post-welding treatment

(1) Preheating: Preheat the sample at a temperature of 500 to 550℃ for 1 to 2 hours by an electric furnace.

(2) Welding rods: Use a Stellite 6 welding rod with a thickness of 4.0 mm; baking temperatures are between 150 and 200℃ and the baking time is from 1 to 1.5 hours.

(3) Post-welding heat treatment: Conduct the post-welding heat treatment around 650℃ for 1.5 to 2 hours by an electric furnace.

1.4 Testing methods

When the welding current, voltage and height of the surfacing surface are different, the samples are surfaced. See the Table 1 for surfacing process parameters.

Table 1 Surfacing process parameters

| Items | Current (A) | Voltage (V) | Welding height (mm) | Items | Current (A) | Voltage (V) | Welding height (mm) |

| 1 | 100 | 15 | 3 | 9 | 150 | 25 | 11 |

| 2 | 100 | 15 | 6 | 10 | 150 | 35 | 3 |

| 3 | 100 | 25 | 3 | 11 | 150 | 35 | 6 |

| 4 | 100 | 25 | 6 | 12 | 200 | 15 | 6 |

| 5 | 100 | 35 | 11 | 13 | 200 | 15 | 11 |

| 6 | 150 | 15 | 6 | 14 | 200 | 25 | 3 |

| 7 | 150 | 25 | 3 | 15 | 200 | 25 | 11 |

| 8 | 150 | 25 | 6 | 16 | 200 | 35 | 6 |

The roughness of the sealing surface of the welded samples after surfacing is Ra 6.4 μm, and penetrant testing is carried out to check for gas holes and cracks. Measure three different points of the parts on each specimen which are 4mm away from the base material to check the hardness (Rockwell Hardness HRC). The metallographic analysis is performed for the samples involved in the analysis of hardness changes and find out the main factors affecting the hardness of the surfacing surface.

2. Testing results

2.1 Observation results for samples

Samples 1 to 5 have poor surfacing surfaces. The surfacing surface of the sample 5 is not smooth and there are sharp corners. The sample 6 and 9 have good surfacing surfaces. The sample 7 and 8 have very good surfacing surfaces. Surfacing surfaces of sample 10 to 16 are average; the surfacing surfaces of samples 10 and 16 are not flat and have small sharp shapes. Undercuts occur for sample 15 and 16.

According to the Table 1, it can be found that the height of the surfacing welding surface has no effect on the forming of surfacing surfaces. In fact, only the influence of current and voltage on the forming of surfacing surfaces needs to be considered.

(1) The influence of current on surfacing forming: When the current is 100A, the forming condition is not ideal; when the current reaches 150A, the forming condition is ideal; when the current reaches 200A, the forming condition becomes worse and an undercut occurs. Therefore, when the current changes from 100 to 200A, the overall forming condition of the surfacing surface changes as follows: bad→good→average. When the current is too great, it will cause undercuts.

(2)The influence of voltage on forming: When the current is constant at 100A, and the voltage changes among 15V, 25V and 35V. The surfacing surfaces formed at voltages of 15V and 25V are not good. The surfacing surface formed at voltages of 35V has uneven surfacing surface. When the current stays at 150A and the voltage increases, the surfacing welding surface is formed from being good, being average to being not flat. When the current is kept at 200A and the voltage changes between 15V and 25V, the surfacing surface is average. When the voltage is 35V, the surfacing surface becomes uneven.

Next: Optimization of Surfacing Welding of Forged Steel Valve Bodies (Part Two)

Previous: Development of High-pressure Forged Steel Gate Valves for Hydrogenation Equipment (Part Three)

News

About Us

Best Categories

Useful Links