Matters Related to Forged Steel Flanged Gate Valves

Matters Related to Forged Steel Flanged Gate Valves

Apr 13, 2021

Forged steel flanged gate valves

The bonnet of the forged steel flanged gate valve is divided into three types: bolted bonnets, welded bonnets, and pressure self-tightening bonnets. This kind of valve has the main feature of having rising stems with brackets, and the integral valve body is a flange. The flat-bottomed valve seat design reduces the fluid pressure and makes the flow smooth, which makes the valve widely used as a regulating and intercepting device on fluid pipelines such as tap water, sewage, construction, food, electric power, medicine, metallurgy, light textile and energy systems.

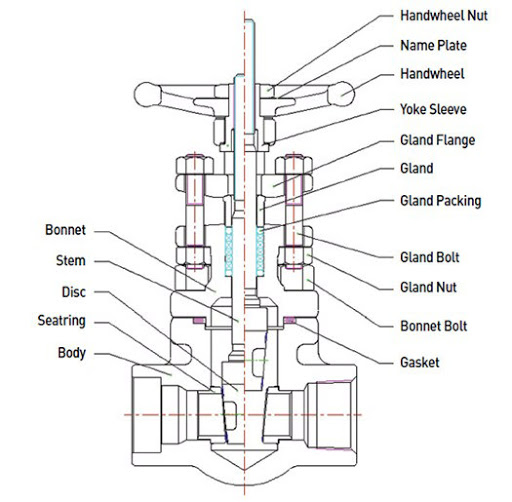

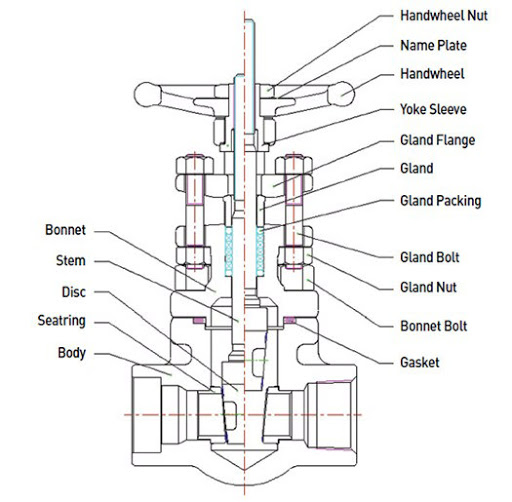

The structure diagram of the forged steel flange gate valve

Characteristics of forged steel flanged gate valves are as follows:

1. The structure design of the flat-bottomed valve seat is adopted to eliminate the accumulation of impurities and reduce the fluid resistance so that the circulation can be smoother.

2. It's easy to open and close the forged steel flanged gate valves, which saves strength.

3. The installation is convenient; the flow direction of media is relatively restricted, which means there is no limitation.

4. The structure is simple; the sealing is good, and the manufacturing process is exquisite.

Installation of forged steel flanged gate valves

1. Clean the inside of the valve before installation, and there should be no impurities in the valve cavity as well as on the sealing surface.

2. Evenly tighten the bolts with force, which connect each part.

3. Check whether the packing is tight or not, so that the packing is tightly sealed and the wedge can be opened and closed flexibly.

4. Check the valve's model, size and other information before installation, and the flow direction of the medium must be consistent with the specified flow direction.

5. When installing, reserve a certain space to facilitate the operation of the valve's actuator.

6. Strictly follow the instructions of the wiring diagram and arrange the wiring of the actuator.

7. After installation, the forged steel flanged gate valve must be maintained regularly.

Topper Forged Valve Manufacturer is a high-tech manufacturer, specializing in the production of forged steel gate valves, forged steel ball valves, forged steel check valves, forged steel globe valves, forged integral flanged valves, forged steel strainers, etc., which has advanced production technology, high-quality products, good service, fast transportation, low prices as well as a good reputation in the valve market in China. If you need a forged steel valve manufacturer for your project, we will be a very good choice for you.

The bonnet of the forged steel flanged gate valve is divided into three types: bolted bonnets, welded bonnets, and pressure self-tightening bonnets. This kind of valve has the main feature of having rising stems with brackets, and the integral valve body is a flange. The flat-bottomed valve seat design reduces the fluid pressure and makes the flow smooth, which makes the valve widely used as a regulating and intercepting device on fluid pipelines such as tap water, sewage, construction, food, electric power, medicine, metallurgy, light textile and energy systems.

The structure diagram of the forged steel flange gate valve

Characteristics of forged steel flanged gate valves are as follows:

1. The structure design of the flat-bottomed valve seat is adopted to eliminate the accumulation of impurities and reduce the fluid resistance so that the circulation can be smoother.

2. It's easy to open and close the forged steel flanged gate valves, which saves strength.

3. The installation is convenient; the flow direction of media is relatively restricted, which means there is no limitation.

4. The structure is simple; the sealing is good, and the manufacturing process is exquisite.

Installation of forged steel flanged gate valves

1. Clean the inside of the valve before installation, and there should be no impurities in the valve cavity as well as on the sealing surface.

2. Evenly tighten the bolts with force, which connect each part.

3. Check whether the packing is tight or not, so that the packing is tightly sealed and the wedge can be opened and closed flexibly.

4. Check the valve's model, size and other information before installation, and the flow direction of the medium must be consistent with the specified flow direction.

5. When installing, reserve a certain space to facilitate the operation of the valve's actuator.

6. Strictly follow the instructions of the wiring diagram and arrange the wiring of the actuator.

7. After installation, the forged steel flanged gate valve must be maintained regularly.

Topper Forged Valve Manufacturer is a high-tech manufacturer, specializing in the production of forged steel gate valves, forged steel ball valves, forged steel check valves, forged steel globe valves, forged integral flanged valves, forged steel strainers, etc., which has advanced production technology, high-quality products, good service, fast transportation, low prices as well as a good reputation in the valve market in China. If you need a forged steel valve manufacturer for your project, we will be a very good choice for you.

Next: The Processing of Guide Grooves of Forged Steel Gate Valves' Wedges

Previous: Optimization of Surfacing Welding of Forged Steel Valve Bodies (Part Two)

News

About Us

Best Categories

Useful Links