Forging Hollow Valve Spheres

Forging Hollow Valve Spheres

Oct 31, 2023

The hollow sphere is an important part of the forged valve. In addition to good corrosion resistance, high impact is also required. Therefore, OCrI7Ni12Mo2 austenitic stainless steel is used for forging.

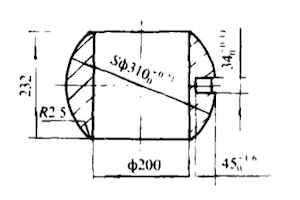

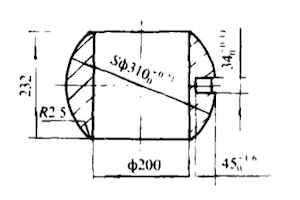

Figure 1 The diagram of parts

1. About the forging performance of OCr17Ni12Mo2

The deformation resistance of OCr17Ni12Mo2 at high temperatures is about twice that of carbon structural steel and alloy structural steel, and there is no allotropic transformation in the heating process. It has poor thermal conductivity and a narrow forging temperature range; considering the danger line of high and low temperatures, we selected the forging temperature temperatures between 1180° to 870°C.

2. Determination of forging drawings and processing of several dimensions

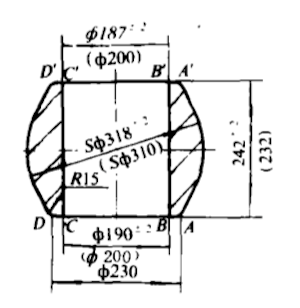

(1) Considering that when the mold is used to forge, the metal flow fills the upper and lower cavities at different speeds, and the error is relatively great. Therefore, to ensure that the height of the part is 232mm, we select the dividing line as the parting surface in the height. When this dimension is used, a margin of 6mm is added to the upper end and a margin of 4mm is added to the lower end. Therefore, the height of the forging is 242mm, which better compensates for the error of the forging.

(2) For the horizontal size 310mm, 200mm is also a size that is difficult to control. It is affected by misalignment and oxide scale. In the design, if the single side margin of 310mm is 4mm, and the outer diameter of the sphere becomes 318mm; the inner hole of 200mm is guaranteed by the mandrel, so the unilateral allowance at the lower end is 5mm, and the unilateral allowance at the upper end is 6.5mm. The upper aperture is 187mm, and the lower aperture is 190mm.

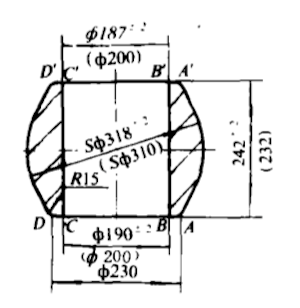

(3) For the treatment of the upper and lower end surfaces, R2.5 is used at the intersection of St318mm and 190mm (or 187mm). For the treatment of the upper and lower end surfaces, if R2.5 is used to transition the intersection of 318mm and 190mm (or 187mm), this size is the most difficult to control because the plasticity of OCrI7Ni12Mo2 is poor and the mold is formed. To fill this small fillet is very difficult. The area of the upper and lower end surfaces is expanded; 20mm is used for AB, CD, A'B and C'D', and then made 318 tangents from points A, D, A', D', and connected the tangents with the upper and lower end with R15. The lower end surface forms a shape in which the upper and lower circular cones are tangent to the middle sphere as shown in Figure 2.

3. Preparation

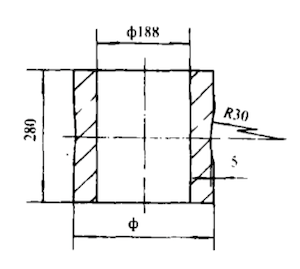

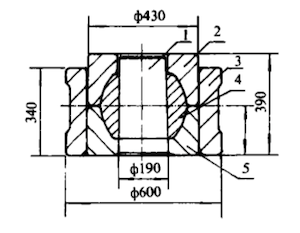

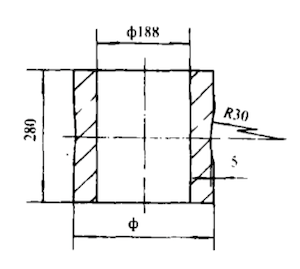

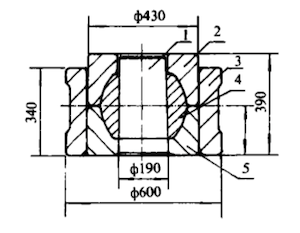

It is calculated that the forging weight is 75kg; the core material weight is 2kg, the fire consumption gravity 4kg, the blanking weight 81kg, and the blanking size 210×297. Perform heating, upsetting, punching and expanding to make a blank as shown in Figure 3. Finally, it is forged and formed in the mold shown in Figure 4. By arranging the process in this way, the forging can be made without skin. In the blank making process, the holes are punched first, and then the holes are enlarged on the carriage. If there is any eccentricity, it can be corrected, and the final forming is carried out in the die cavity. The internal organization of the sphere is well improved. The mold removal operation is also more convenient.

Figure 3

Figure 4

1. Mandrel 2. Upper dies 3. Mold sets 4. Forging 5. Lower dies

Figure 1 The diagram of parts

1. About the forging performance of OCr17Ni12Mo2

The deformation resistance of OCr17Ni12Mo2 at high temperatures is about twice that of carbon structural steel and alloy structural steel, and there is no allotropic transformation in the heating process. It has poor thermal conductivity and a narrow forging temperature range; considering the danger line of high and low temperatures, we selected the forging temperature temperatures between 1180° to 870°C.

2. Determination of forging drawings and processing of several dimensions

(1) Considering that when the mold is used to forge, the metal flow fills the upper and lower cavities at different speeds, and the error is relatively great. Therefore, to ensure that the height of the part is 232mm, we select the dividing line as the parting surface in the height. When this dimension is used, a margin of 6mm is added to the upper end and a margin of 4mm is added to the lower end. Therefore, the height of the forging is 242mm, which better compensates for the error of the forging.

(2) For the horizontal size 310mm, 200mm is also a size that is difficult to control. It is affected by misalignment and oxide scale. In the design, if the single side margin of 310mm is 4mm, and the outer diameter of the sphere becomes 318mm; the inner hole of 200mm is guaranteed by the mandrel, so the unilateral allowance at the lower end is 5mm, and the unilateral allowance at the upper end is 6.5mm. The upper aperture is 187mm, and the lower aperture is 190mm.

(3) For the treatment of the upper and lower end surfaces, R2.5 is used at the intersection of St318mm and 190mm (or 187mm). For the treatment of the upper and lower end surfaces, if R2.5 is used to transition the intersection of 318mm and 190mm (or 187mm), this size is the most difficult to control because the plasticity of OCrI7Ni12Mo2 is poor and the mold is formed. To fill this small fillet is very difficult. The area of the upper and lower end surfaces is expanded; 20mm is used for AB, CD, A'B and C'D', and then made 318 tangents from points A, D, A', D', and connected the tangents with the upper and lower end with R15. The lower end surface forms a shape in which the upper and lower circular cones are tangent to the middle sphere as shown in Figure 2.

3. Preparation

It is calculated that the forging weight is 75kg; the core material weight is 2kg, the fire consumption gravity 4kg, the blanking weight 81kg, and the blanking size 210×297. Perform heating, upsetting, punching and expanding to make a blank as shown in Figure 3. Finally, it is forged and formed in the mold shown in Figure 4. By arranging the process in this way, the forging can be made without skin. In the blank making process, the holes are punched first, and then the holes are enlarged on the carriage. If there is any eccentricity, it can be corrected, and the final forming is carried out in the die cavity. The internal organization of the sphere is well improved. The mold removal operation is also more convenient.

Figure 3

Figure 4

1. Mandrel 2. Upper dies 3. Mold sets 4. Forging 5. Lower dies

Next: Defects of Forged Copper Valves

Previous: Forged Steel Gate Valves

News

About Us

Best Categories

Useful Links