Development of High-pressure Forged Steel Gate Valves for Hydrogenation Equipment (Part Two)

Development of High-pressure Forged Steel Gate Valves for Hydrogenation Equipment (Part Two)

Mar 03, 2021

Table 1 Selection of main body materials and internal materials

| Valve bodies | ASTM A216 WCB/ ASTM A105 |

ASTM A217 WC6/ ASTM A182 F11 CL2 |

ASTM A351 CF8C/ASTM A182 F321, F347 |

| Packing gaskets | ASTM A105 |

ASTM A182 F11 CL2 |

ASTM A182 F321, F347 |

| Valve seats | ASTM A105 plus S116 |

ASTM A182 F11 CL2 plus STL6 |

ASTM A182 F321, F347 plus STL6 |

| Valve discs | ASTM A216 WCB plus STL6/ASTM A105+STL6 | ASTM A217 WC6 plus STL6/ASTM A182 F11 CL2+STL6 | ASTM A351 CF8C plus STL6/ASTM A182 F321, F347 plus STL6 |

| Valve stems | ASTM A182 F6a CI2 |

ASTM A182 F6a CL2 |

ASTM A182 F321, F347 |

| Sealing rings | Flexible graphite ring plus 304 | Flexible graphite ring plus 304 | Flexible graphite ring plus 321, 347 |

| Middle flange bolts/nuts | ASTM A193 B7M/ ASTM A194 2HM |

ASTM A193 B16/ ASTM A194 4 | ASTM A193 B8/ ASTM A194 8 |

| Packing | The carbon content should be greater than 99.7%; temperature resistance is higher than 610℃; the friction factor is lower than 0.1; corrosion inhibitor temperature is higher than 700℃; diameters of stainless steel wire are not less than 0.1 mm and each share contains not less than 3 strands of steel wires. | ||

4. Structure design

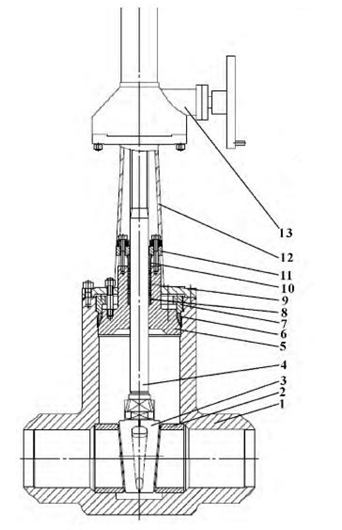

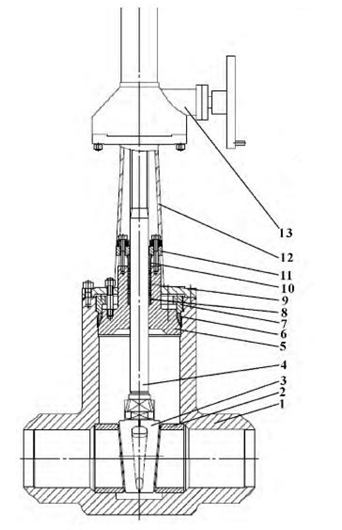

The pressure self-sealing bonnet structure is adopted, taking a forged steel valve with a size of DN200 mm and pressure of PN25MPa as an example; its structure diagram is shown in the Figure 1. The valve plate has three structures: single plates, double parallel and double split wedge plates and the valve seat has two structures such as wedge valve seats and parallel double valve seats.

5.1 The structure of main parts

5.1.1 Structural design of main parts

Because the working conditions of the high-pressure hydrogenation unit are more sensitive to the defects of the medium material itself, if the material has non-metallic inclusions, slag inclusions, gas holes, cracks and other discontinuous defects, it is easy to cause the accumulation of hydrogen. Hydrogen deformation will occur and even induces micro-cracks due to partial high pressure at room temperature. At the same time, brittleness of the material will worsen (hydrogen embrittlement). At high temperatures, these defects are more conducive to the progress of hydrogen-induced internal decarburization, thereby accelerating the process of hydrogen corrosion and cracking of materials. The hydrogen sulfide medium is more sensitive to the external discontinuous defects of the material, especially in the wet hydrogen sulfide environment; the external discontinuous defects often become the inducement of stress corrosion cracking. Therefore, according to the working conditions of the hydrogenation valve, the main parts such as the valve body and valve bonnet all adopt a dense forging structure. In order to prevent the occurrence of sulfide stress corrosion cracking (SSC) in the weak area of the valve stress concentration due to factors such as the PH value, HS concentration and stress in the medium. When the structure of the valve body and other parts is designed, the radius of the rounded corners of the transition zone is enlarged as far as possible at the corner so as to obtain smooth transition for the wall thickness of the valve body from small to large and make the internal structure in contact with the medium not appear sharp corners; all rounded corners are used.

5.1.2 Process analysis of valve body parts structure and general structure design

The biggest problem in the development of high-pressure forged steel gate valves for hydrogenation units is the form of valve body forgings. Since the application of multi-directional die technology of valve bodies in China is still in its infancy, there is no multi-directional die forging equipment for valve bodies above DN150mm, resulting in the structural manufacturability of valve body forgings being relatively poor. At the same time, the manufacturing cost of multi-directional dies is very expensive, and it is difficult for a single valve manufacturer to form large quantities to offset the die costs. Therefore, the forging form of the valve body of the hydrogenation valve at this stage is between free forging and die forging.

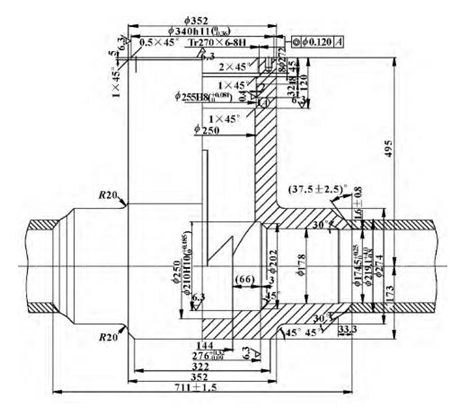

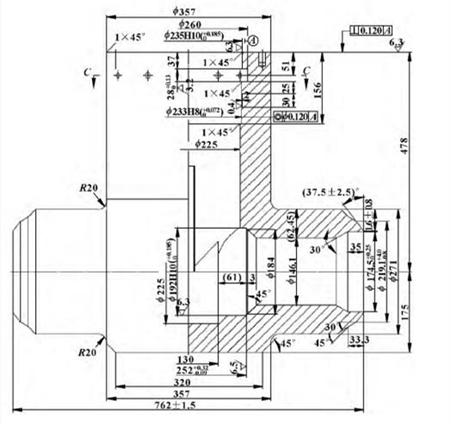

Because of the high material cost and long production cycle of free forging, the relationship between the inner diameter and outer diameter of a valve whose diameters and pressure are between DN150 and 300mm as well as 25MPa and 42MPa is studied, that is, a valve with high pressure, small inner diameters and great wall thickness. This rule makes the difference between the outer diameter of the channel and outer diameter of middle valves with the same diameter and different pressure small. Unite the channel of outer diameter with relatively small absolute difference value and relatively difference value with the outer diameter of the middle part on the basis of finite element analysis, so that the forging profiles of the same diameter and different pressure have the common channel outer diameter and inner cavity outer diameter. Take a valve with a size of DN200 mm and pressure of PN25MPa as well as DN200 mm & PN42 MPa as an example. The valve body parts are shown in the Figure 2 and Figure 3. The outer diameter of the channel is $274 mm, and that of the middle cavity is $357 mm. This feature makes the mold cavity that costs most in the forging die universal. Changing the blank size and punching punch can obtain valve body forgings with different pressure, which greatly saves expensive die costs. The general design of the valve body of the wedge gate valve, parallel double disc gate valve and wedge double disc gate valve with the same diameter and different pressure has greatly improved the generalization of the pressure self-sealing valve and greatly made the multi-directional die forging possible in the high-end valve market in China.

Figure 1 The diagram of forged steel gate valve mechanisms with a size of DN200 mm and pressure of PN25MPa

5.1 The structure of main parts

5.1.1 Structural design of main parts

Because the working conditions of the high-pressure hydrogenation unit are more sensitive to the defects of the medium material itself, if the material has non-metallic inclusions, slag inclusions, gas holes, cracks and other discontinuous defects, it is easy to cause the accumulation of hydrogen. Hydrogen deformation will occur and even induces micro-cracks due to partial high pressure at room temperature. At the same time, brittleness of the material will worsen (hydrogen embrittlement). At high temperatures, these defects are more conducive to the progress of hydrogen-induced internal decarburization, thereby accelerating the process of hydrogen corrosion and cracking of materials. The hydrogen sulfide medium is more sensitive to the external discontinuous defects of the material, especially in the wet hydrogen sulfide environment; the external discontinuous defects often become the inducement of stress corrosion cracking. Therefore, according to the working conditions of the hydrogenation valve, the main parts such as the valve body and valve bonnet all adopt a dense forging structure. In order to prevent the occurrence of sulfide stress corrosion cracking (SSC) in the weak area of the valve stress concentration due to factors such as the PH value, HS concentration and stress in the medium. When the structure of the valve body and other parts is designed, the radius of the rounded corners of the transition zone is enlarged as far as possible at the corner so as to obtain smooth transition for the wall thickness of the valve body from small to large and make the internal structure in contact with the medium not appear sharp corners; all rounded corners are used.

5.1.2 Process analysis of valve body parts structure and general structure design

The biggest problem in the development of high-pressure forged steel gate valves for hydrogenation units is the form of valve body forgings. Since the application of multi-directional die technology of valve bodies in China is still in its infancy, there is no multi-directional die forging equipment for valve bodies above DN150mm, resulting in the structural manufacturability of valve body forgings being relatively poor. At the same time, the manufacturing cost of multi-directional dies is very expensive, and it is difficult for a single valve manufacturer to form large quantities to offset the die costs. Therefore, the forging form of the valve body of the hydrogenation valve at this stage is between free forging and die forging.

Because of the high material cost and long production cycle of free forging, the relationship between the inner diameter and outer diameter of a valve whose diameters and pressure are between DN150 and 300mm as well as 25MPa and 42MPa is studied, that is, a valve with high pressure, small inner diameters and great wall thickness. This rule makes the difference between the outer diameter of the channel and outer diameter of middle valves with the same diameter and different pressure small. Unite the channel of outer diameter with relatively small absolute difference value and relatively difference value with the outer diameter of the middle part on the basis of finite element analysis, so that the forging profiles of the same diameter and different pressure have the common channel outer diameter and inner cavity outer diameter. Take a valve with a size of DN200 mm and pressure of PN25MPa as well as DN200 mm & PN42 MPa as an example. The valve body parts are shown in the Figure 2 and Figure 3. The outer diameter of the channel is $274 mm, and that of the middle cavity is $357 mm. This feature makes the mold cavity that costs most in the forging die universal. Changing the blank size and punching punch can obtain valve body forgings with different pressure, which greatly saves expensive die costs. The general design of the valve body of the wedge gate valve, parallel double disc gate valve and wedge double disc gate valve with the same diameter and different pressure has greatly improved the generalization of the pressure self-sealing valve and greatly made the multi-directional die forging possible in the high-end valve market in China.

Figure 1 The diagram of forged steel gate valve mechanisms with a size of DN200 mm and pressure of PN25MPa

1. Valve bodies 2. Valve seats 3. Valve discs 4. Stems 5. Valve bonnets 6. Self-tightening seal rings 7. Support plates 8. Packing pads 9. Sealing parts of packing 10. Packing bushings 11. Packing plates 12. Brackets 13. Gear boxes

Figure 2 The drawing for valve body parts with a size of DN200 mm and pressure of PN25MPa

Figure 3 The drawing for valve body parts with a size of DN200 mm and pressure of PN42MPa

5.2 Sealing structure

Pressure self-sealing valve bonnet structure is adopted. Although the pressure self-sealing bonnet has complex structure, high processing requirements and many links that affect the sealing, there is no fatal disadvantages of bolted bonnets which creep and relax under long-term alternating stress conditions; it has advantages of forging technology and material costs being incomparable. The self-sealing valve bonnet structure with a self-sealing wedge angle of between 20° to 25° is selected based on the long-term practical experience.

Next: Development of High-pressure Forged Steel Gate Valves for Hydrogenation Equipment (Part Three)

Previous: Development of High-pressure Forged Steel Gate Valves for Hydrogenation Equipment (Part One)

News

About Us

Best Categories

Useful Links