Ultra High Pressure and Small Diameter Forged Steel Globe Valves

Ultra High Pressure and Small Diameter Forged Steel Globe Valves

Dec 25, 2020

The structural characteristics of the new ultra high pressure and small diameter forged steel globe valve are discussed and performance of commonly used forged steel globe valves with small diameters is introduced in this article.

1. Overview

In view of the situation that several commonly used ultra high pressure small diameter forged steel globe valves often leak at sealing positions of valve stems during use. The middle cavity structure of the valve is improved, and a new type of globe valve is designed.

2. Analysis

Conventional ultra high pressure and small diameter forged steel globe valves can be divided into integral, self-tightening and group welding types.

1. Overview

In view of the situation that several commonly used ultra high pressure small diameter forged steel globe valves often leak at sealing positions of valve stems during use. The middle cavity structure of the valve is improved, and a new type of globe valve is designed.

2. Analysis

Conventional ultra high pressure and small diameter forged steel globe valves can be divided into integral, self-tightening and group welding types.

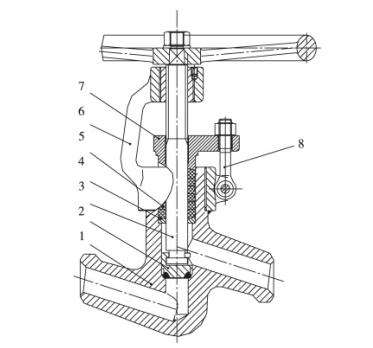

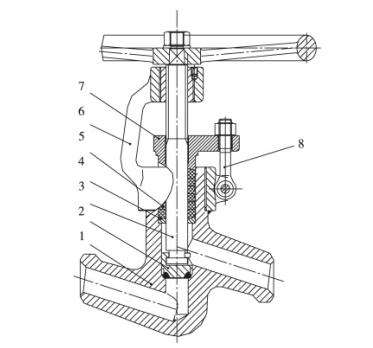

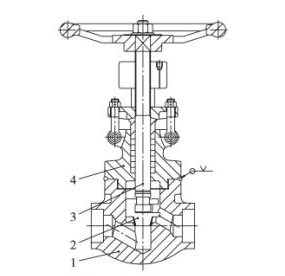

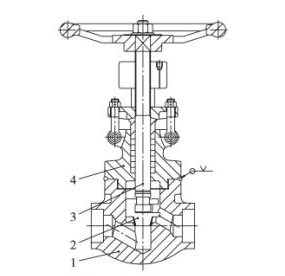

(1) The integral type

The integral of the valve stem and body is showed in figure 1. The seal of the valve stem is obtained by the packing gland pressing the packing. The middle cavity is short and thin, which saves costs. However, the valve stand is directly connected to the valve body. If the eyelet bolt or stand breaks, it may cause the valve stem to rush out. There are safety hazards for ultra high pressure valves.

Figure 1 The integral globe valve

1. Valve bodies 2. Valve clacks 3. Stems 4. Packing pads 5. Packing 6. Stands 7. Packing glands 8. Eyelet bolts

Figure 1 The integral globe valve

1. Valve bodies 2. Valve clacks 3. Stems 4. Packing pads 5. Packing 6. Stands 7. Packing glands 8. Eyelet bolts

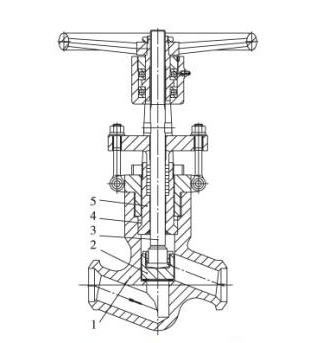

(2) The self-tightening seal type

The self-tightening seal type is showed in the figure 2. The medium of the self-tightening globe valve acts on the middle cavity of the valve body to push the bonnet to rise to the bonnet part, obtaining the upper seal. The pressure does not directly act on the packing pad. The higher the pressure is, the greater the pressure on the sealing ring becomes, and the better the sealing effect will be. The structure solves the leakage problem in the middle cavity, and maintenance is convenient. However, the middle cavity of the structure is too big, which leads to an increase in the force bearing area of the stand, and increases the manufacturing cost. Therefore, it is not suitable for valves with small diameters.

Figure 2 The self-tightening seal globe valve

1. Valve bodies 2. Discs 3. Valve stems 4. Seal rings 5. Valve bonnets

Figure 2 The self-tightening seal globe valve

1. Valve bodies 2. Discs 3. Valve stems 4. Seal rings 5. Valve bonnets

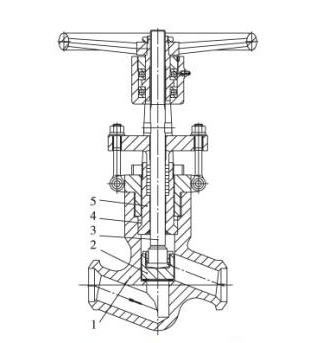

(3) The group welding type

The group welding type is showed in the figure 3. The body and bonnet of the group welded globe valve are connected by threaded connections and then they are group-welded to effectively prevent leakage at the thread part. After the valve body and bonnet are welded together, maintenance of the valve is affected. When the sealing surface leaks especially, the welding point of the valve must be destroyed, causing the entire valve to be scrapped.

Figure 3 Group welded globe valves

1. Valve bodies 2. Valve clacks 3. Stems 4. Valve bonnets

3. Improvement

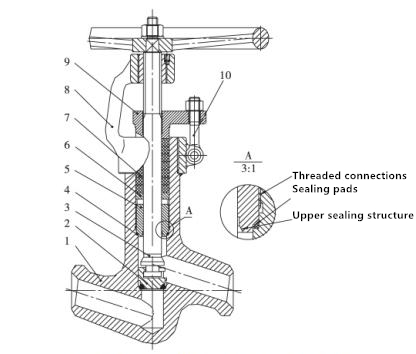

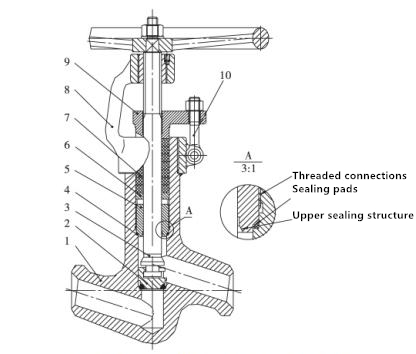

After analysis, the integral globe valve structure of the valve body and bonnet threaded connection was optimized and a sealing seat was added (Figure 4). The sealing seat and the valve body are connected by threads, and thread strength is calculated to satisfy fixing functions of the valve under high pressure. The sealing seat is slotted, and it can be screwed into or out of the valve body with special tools. Wedge shaped flexible graphite with stainless steel wire is installed outside the lower end of the sealing seat.

Figure 4 The new type globe valve

Figure 3 Group welded globe valves

1. Valve bodies 2. Valve clacks 3. Stems 4. Valve bonnets

3. Improvement

After analysis, the integral globe valve structure of the valve body and bonnet threaded connection was optimized and a sealing seat was added (Figure 4). The sealing seat and the valve body are connected by threads, and thread strength is calculated to satisfy fixing functions of the valve under high pressure. The sealing seat is slotted, and it can be screwed into or out of the valve body with special tools. Wedge shaped flexible graphite with stainless steel wire is installed outside the lower end of the sealing seat.

Figure 4 The new type globe valve

1. Valve bodies 2. Discs 3. Stems 4. Sealing gaskets 5. Sealing seats 6. Packing pads 7. Packing 8. Stands 9. Packing glands 10. Eyelet bolts

Seal rings can avoid the medium leaking from the thread part. The sealing seat has an upper sealing function. After the valve is opened, the valve stem acts on the sealing seat to form an upper seal, so that the packing can not be affected by the medium, extending the service life of the packing and realizing the replacement of the packing under pressure. The sealing seat has the function of preventing the valve stem from coming out when the stand or the eyelet bolt is broken, and the occurrence of accidents is avoided.

4. Conclusion

The new ultra high pressure small diameter forged steel globe valve adopts the sealing seat structure, which reduces the diameter of the middle valve cavity, improves valve quality, saves materials, and is convenient for disassembly and maintenance. The valve internals such as valve stems and discs can be replaced by removing the packing and packing pad and unscrewing the sealing seat.

Next: Water-cooled High Temperature Forged Steel Valves

Previous: Design and Application Prospects of Forged Steel Ammonia Valves

News

About Us

Best Categories

Useful Links