The Structural Design of Forged Slab Gate Valves without Welding Seams

The Structural Design of Forged Slab Gate Valves without Welding Seams

Nov 12, 2021

A kind of forged slab gate valve without a welding seam is introduced, and its overall structure, bonnet structure, installation methods of valve seats and connections between valve stems and valve plates are introduced in this article, which reflects the practicability and maneuverability of the product in terms of structure, technology, performance and so on. The product has been patented.

1. Overview

With the continuous progress of modern technology and industry, petrochemical, natural gas and other industries have developed rapidly, and more and more complex working conditions and products with higher requirements have emerged. As an important component of long-distance pipelines in the petrochemical industry, valves are facing more and more stringent requirements and working conditions. As a common valve in the petrochemical industry, the slab gate valve's performance and service life particularly rely on materials and manufacturing processes of the valve body.

The main body of the valve is usually made by casting due to the characteristics of the internal structure of the traditional slab gate valve. The inherent defects of the casting process such as gas holes, shrinkage porosity, sand inclusion, blowholes and cracks will affect the performance, service life, and application of the product. If the valve body of the traditional slab gate valve is made by the forging process, casting defects can be avoided. However, there will be a lot of welded structure in the valve body and bonnet. The traditional forged slab gate valve is still limited when there are high requirements and strong corrosive conditions due to the defects of the welding seam such as gas holes, slag inclusion, incomplete welding, and pits as well as the existence of factors such as post-weld stress relief treatment and the weldability of the main material.

In order to adapt to high-pressure and strong corrosion conditions, an integrated forged slab gate valve without welding seams was developed. The pressure rating is Class 900, and the H2S content in the medium is 15%. The valve body is made from nickel alloy 625 by forging.

2. Structural features

2.1 Overall structure

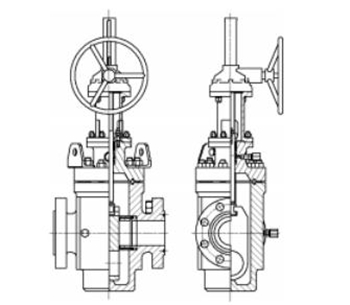

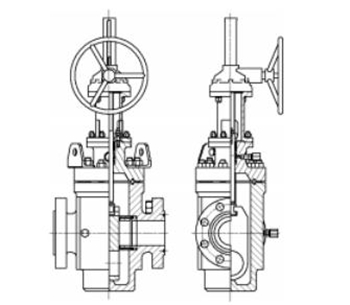

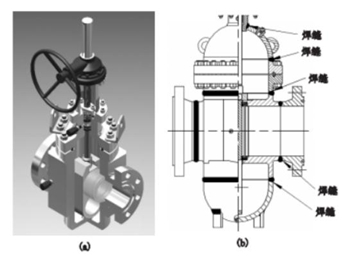

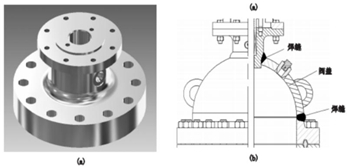

The forged slab gate valve without welding seams has main parts such as valve bodies, valve bonnets, valve plates, valve stems and valve seats, which is forged as a whole and then machined, as shown in Figure 1. The shell is made of forged steel, which has uniform structure, fineness, high strength, clean appearance, compact internal structure, good practicability, no welding for the main structure, and no external leakage. At the same time, the size deviation between the thermal stress deformation of the valve body and the center of the flow channel and valve body caused by welding and due to welding are prevented. The process of annealing and heat treatment to eliminate stress after welding is not necessary. The structural comparison is shown in Figure 2.

Figure 1 Forged slab gate valves without welding seams

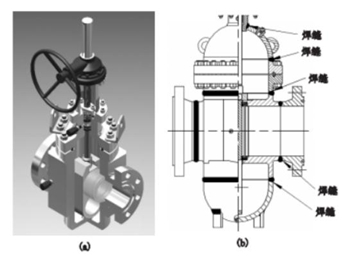

(a) Integrated forged structure without welding seams (b) Traditional welded structure

Figure 2 A comparison of integrated forging structure and traditional welding structure

2.2 The structure of the bonnet

The bonnet is forged as a whole and then machined. The main body is not welded, which ensures the advantages of forged steel. At the same time, the deviation of the center size of the bonnet caused by welding and the thermal stress deformation of the bonnet due to welding are prevented, and the process of annealing and heat treatment after welding is not needed. Check figure 3 for the structure comparison of the valve bonnet.

2.3 The installation method of the valve seat

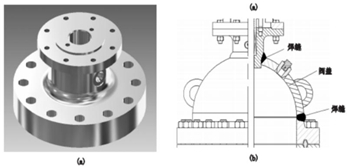

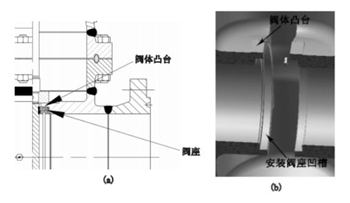

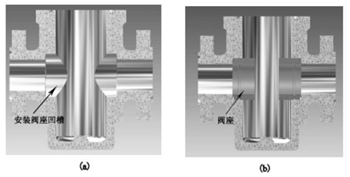

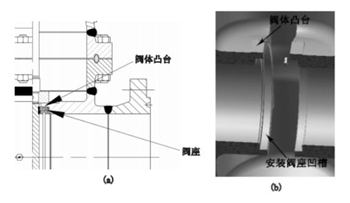

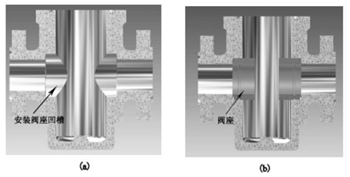

The valve seat's installation method is different inside the valve body compared with the traditional slab gate valve. The valve seat of the traditional forged steel slab gate valve body must be provided with a boss (Figure 4), and a groove inside the boss for installing the valve seat must be provided. Grooves can be directly machined inside the valve body for installation of the valve seat for forged steel slab gate valves without welding seams (Figure 5).

2.4 Connections of valve stems and plates

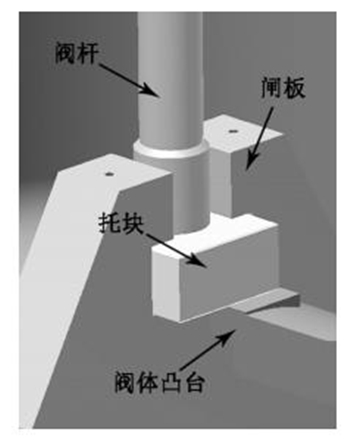

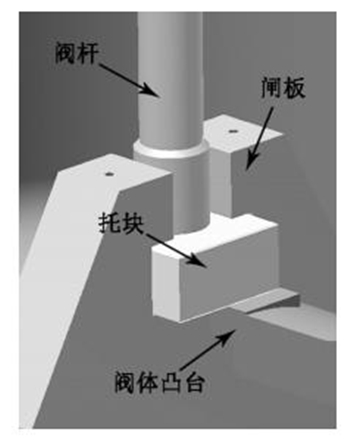

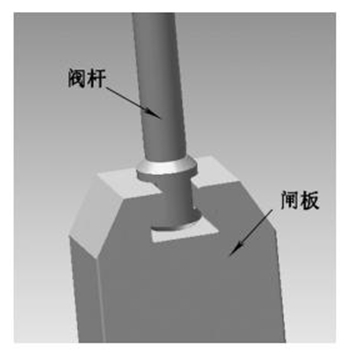

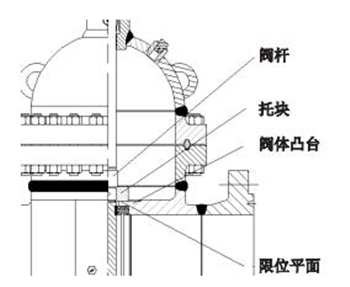

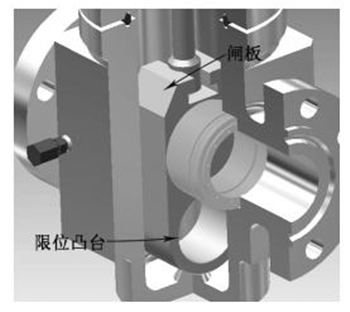

The connection between the valve stem and plate is different from that of the traditional slab gate valve. The traditional forged steel slab gate valve uses the valve stem to connect the bracket block, and the valve plate is connected to the bracket block. The bracket is used as a connect to achieve the purpose of the valve stem driving the valve plate to move up and down, and the bracket and valve body boss realize the mechanical limit of the full opening of the valve. A groove is directly provided for the valve stem of the forged steel slab gate valve, and the valve stem groove and upper structure of the valve plate are limited by the stroke. The valve plate moves up and down driven by the valve stem through the groove. The mechanical limit of the full opening of the valve is realized by the boss at the bottom of the valve body and valve plate. Figures 6 to 9 show the comparison of the connection between the traditional valve stem and valve plate and that between the valve stem and valve plate without welding seams.

(a) Valve bonnets without welding seams (b) Conventional valve bonnets

Figure 3 A structural comparison of valve bonnets without welding seams and traditional valve bonnets

(a) Plane structure (b) Stereoscopic structure

Figure 4 Installing seats of traditional forged steel slab gate valves

(a) Installation of the valve seat groove (b) Valve seats

Figure 5 Installation of valve seats of forged steel slab gate valves without welding seams

Figure 6 The traditional connection between the valve stem and valve plate

1. Overview

With the continuous progress of modern technology and industry, petrochemical, natural gas and other industries have developed rapidly, and more and more complex working conditions and products with higher requirements have emerged. As an important component of long-distance pipelines in the petrochemical industry, valves are facing more and more stringent requirements and working conditions. As a common valve in the petrochemical industry, the slab gate valve's performance and service life particularly rely on materials and manufacturing processes of the valve body.

The main body of the valve is usually made by casting due to the characteristics of the internal structure of the traditional slab gate valve. The inherent defects of the casting process such as gas holes, shrinkage porosity, sand inclusion, blowholes and cracks will affect the performance, service life, and application of the product. If the valve body of the traditional slab gate valve is made by the forging process, casting defects can be avoided. However, there will be a lot of welded structure in the valve body and bonnet. The traditional forged slab gate valve is still limited when there are high requirements and strong corrosive conditions due to the defects of the welding seam such as gas holes, slag inclusion, incomplete welding, and pits as well as the existence of factors such as post-weld stress relief treatment and the weldability of the main material.

In order to adapt to high-pressure and strong corrosion conditions, an integrated forged slab gate valve without welding seams was developed. The pressure rating is Class 900, and the H2S content in the medium is 15%. The valve body is made from nickel alloy 625 by forging.

2. Structural features

2.1 Overall structure

The forged slab gate valve without welding seams has main parts such as valve bodies, valve bonnets, valve plates, valve stems and valve seats, which is forged as a whole and then machined, as shown in Figure 1. The shell is made of forged steel, which has uniform structure, fineness, high strength, clean appearance, compact internal structure, good practicability, no welding for the main structure, and no external leakage. At the same time, the size deviation between the thermal stress deformation of the valve body and the center of the flow channel and valve body caused by welding and due to welding are prevented. The process of annealing and heat treatment to eliminate stress after welding is not necessary. The structural comparison is shown in Figure 2.

Figure 1 Forged slab gate valves without welding seams

(a) Integrated forged structure without welding seams (b) Traditional welded structure

Figure 2 A comparison of integrated forging structure and traditional welding structure

2.2 The structure of the bonnet

The bonnet is forged as a whole and then machined. The main body is not welded, which ensures the advantages of forged steel. At the same time, the deviation of the center size of the bonnet caused by welding and the thermal stress deformation of the bonnet due to welding are prevented, and the process of annealing and heat treatment after welding is not needed. Check figure 3 for the structure comparison of the valve bonnet.

2.3 The installation method of the valve seat

The valve seat's installation method is different inside the valve body compared with the traditional slab gate valve. The valve seat of the traditional forged steel slab gate valve body must be provided with a boss (Figure 4), and a groove inside the boss for installing the valve seat must be provided. Grooves can be directly machined inside the valve body for installation of the valve seat for forged steel slab gate valves without welding seams (Figure 5).

2.4 Connections of valve stems and plates

The connection between the valve stem and plate is different from that of the traditional slab gate valve. The traditional forged steel slab gate valve uses the valve stem to connect the bracket block, and the valve plate is connected to the bracket block. The bracket is used as a connect to achieve the purpose of the valve stem driving the valve plate to move up and down, and the bracket and valve body boss realize the mechanical limit of the full opening of the valve. A groove is directly provided for the valve stem of the forged steel slab gate valve, and the valve stem groove and upper structure of the valve plate are limited by the stroke. The valve plate moves up and down driven by the valve stem through the groove. The mechanical limit of the full opening of the valve is realized by the boss at the bottom of the valve body and valve plate. Figures 6 to 9 show the comparison of the connection between the traditional valve stem and valve plate and that between the valve stem and valve plate without welding seams.

(a) Valve bonnets without welding seams (b) Conventional valve bonnets

Figure 3 A structural comparison of valve bonnets without welding seams and traditional valve bonnets

(a) Plane structure (b) Stereoscopic structure

Figure 4 Installing seats of traditional forged steel slab gate valves

(a) Installation of the valve seat groove (b) Valve seats

Figure 5 Installation of valve seats of forged steel slab gate valves without welding seams

Figure 6 The traditional connection between the valve stem and valve plate

The forged steel slab gate valve without welding seams has an improvement in structural design, process manufacturing and assembly compared with traditional slab gate valves, and it can better play the characteristics of the material, improve the manufacturability and overall performance, reduce material consumption and prolong the service life.

Figure 7 The connection between the valve stem and valve plate of the slab gate valve without welding seams

Figure 8 Traditional forged steel slab gate valves

Figure 9 Forged steel slab gate valves without welding seams

3. Conclusion

The new forged slab gate valve without welding seams can fully reflect the advantages of practicability and operability in terms of product structure, performance and processes, and has also received good feedback in actual use, which proves the improvement after innovation and optimization design of the product. As a result, there is a great prospect for promotion and use in the market.

Next: The Classification and Market Demand of Forged Steel Valves

News

About Us

Best Categories

Useful Links