Forging Process and Production of F91 Gate Valve Bodies

Forging Process and Production of F91 Gate Valve Bodies

Jan 15, 2024

Gate valves serve as crucial control components in fluid transportation systems within industries such as power plants, chemicals, and petroleum. The valve body, a primary component of gate valve structure, functions as a conduit for fluid media, enduring pressure, temperature, and corrosion. F91 steel, classified as an improved 9Cr-1Mo high-strength ferritic heat-resistant steel, exhibits exceptional oxidation resistance, resistance to high-temperature steam corrosion, and impressive impact toughness. Its stable structure at temperatures below 600°C and relatively lower cost make it widely used in manufacturing valve bodies for high-temperature and high-pressure conditions.

Forging Process Implementation:

-

Preparation:

- Formulation of forging process and parameters considering the long-term operation under harsh conditions.

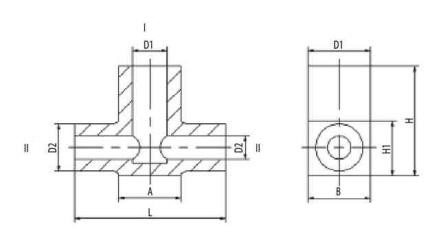

- Emphasis on strength in all three directions of the valve body, ensuring sufficient deformation and grain refinement to eliminate isotropy.

- Minimum forging ratio for valve body: ≥3.5 for electric furnace ingot, ≥3 for electric slag ingot.

- Matching reduction ratios: ≥2 for electric furnace ingot, ≥1.5 for electric slag ingot.

- Alignment of flow direction with media flow for proper streamlining during processing.

-

Implementation of Process:

- First and second heats involve rough upsetting and elongation of the blank.

- Third heat involves shaping the blank to meet mold dimensions, extracting the second stage blank crucial for overall streamline distribution.

- Fourth heat includes final adjustments, blind hole punching, and forging to the finished product.

-

Heat Treatment After Forging:

- Due to F91's sensitivity to cracking, surface defects are cleaned before heat treatment.

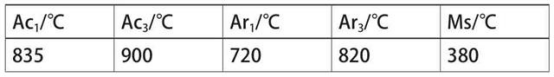

- Prompt normalizing after reaching 500°C, with measures like air cooling or mist spraying to accelerate cooling.

Operational Considerations:

- F91, being a low-carbon high-alloy steel, requires controlled forging temperatures to prevent cracking.

- The last forging ratio should be ≥1.5 to avoid coarse grain structure.

- Prioritize elongation in the second stage forming process within the mold to ensure proper streamline distribution.

Conclusion: The production of F91 and similar high-alloy steel gate valve bodies using free forging equipment requires a rational forging process based on actual part conditions. The use of auxiliary tools like molds significantly reduces excess material, enhances forging precision, and controls fiber flow, ensuring the components meet design specifications. Our company's adoption of this process for the production of gate valve bodies in nuclear and thermal power equipment has resulted in components that fully comply with inspection standards, meeting the strength design requirements.

Next: Forging Medium and High-pressure Valve Bonnets

Previous: Forging Knowledge of Valves