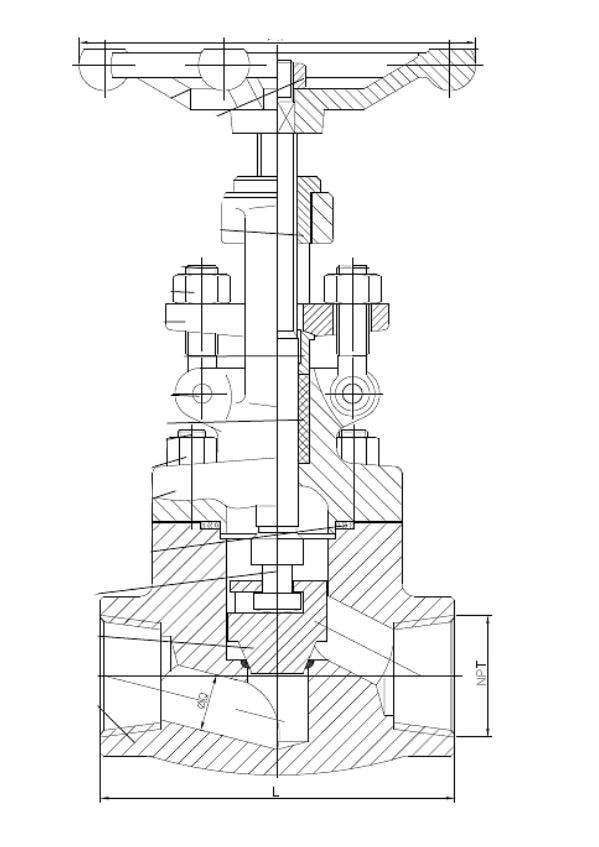

Forged Female Threaded Socket Welded Globe Valves

Forged Female Threaded Socket Welded Globe Valves

Jun 07, 2024

In industries where fluid flow control is paramount, reliable and robust valves are indispensable. The forged female threaded socket welded globe valve has become a popular choice for its strength and longevity. This blog post will delve into the advantages of these valves and discuss why they could be an ideal fit for your operations.

These forged globe valves are favored across various sectors for their precision in controlling fluid flow, particularly in demanding environments such as oil refineries, chemical plants, and power stations. Their popularity stems from their exceptional durability and strength, achieved through forging from premium materials like stainless or alloy steel, which allow them to endure extreme temperatures and pressures while maintaining an effective seal.

The design of forged female threaded socket welded globe valves ensures they provide a tight seal even under high-pressure conditions, a critical feature for many industrial processes. Their straightforward design also simplifies installation and maintenance, as they have few moving parts that require attention, thereby ensuring consistent performance with minimal upkeep.

These valves are not only durable but also known for their longevity, thanks to the uniform grain flow resulting from the forging process, which makes them stronger than cast or machined parts. They are capable of withstanding substantial usage without degrading in performance.

Moreover, the high-pressure capability of these valves is complemented by reinforced components and robust bodies made from materials that resist corrosion and erosion better than cast iron or brass. The globe valve's unique disk-shaped member allows for precise flow regulation, even under the wear caused by frequent operation.

Ease of installation and maintenance is another hallmark of these valves. Their standard threading is compatible with most piping systems, simplifying the installation process. The durable construction means they require less frequent repair or replacement, and cleaning and part replacement, when needed, are manageable.

Forged female threaded socket welded globe valves are also produced in a variety of materials, including carbon steel for cost-effective, non-corrosive applications, stainless steel for environments requiring high corrosion resistance and temperature tolerance, and exotic metals like titanium and zirconium for extreme conditions. This variety allows for precise matching of valve material to application needs.

In conclusion, the forged female threaded socket welded globe valve is a top choice for industries needing valves capable of handling high pressures with ease. They combine durability, ease of maintenance, and a range of material options to provide a reliable and enduring solution. These valves represent a valuable long-term investment for any industry that demands precision and resilience in fluid control.

Next: Introduction to Forged Steel Floating Ball Valves

Previous: Understanding Forged Valve Pressure Ratings for Industrial Safety